Home > Processing equipment > Turnkey process skid > Custom fermentation skids

Custom fermentation skids

for simple and safe operation

Fermentation is a key process in the pharmaceuticals and biotechnology industries (’industrie pharmaceutique et biotechnologique,), calling for precise control over parameters such as temperature, agitation and sterility to guarantee product quality and reproducibility.

ZIEMEX fermentation skids are custom designed to incorporate all the critical stages of the process, from sterilisation of substrates to homogenisation and temperature control of fermenters, while allowing simple and safe operation.

FERMENTATION SKIDS

Technical specifications

ZIEMEX fermentation skids are entirely personalised to meet the requirements of each customer.

They can be made in a wide range of materials ranging from standard stainless steels such as 304L and 316L to high-alloy steels such as duplex, super duplex, titanium, Hastelloy® or zirconium.

Surface conditions are controlled to ensure sterility and cleanability, with finishes up to Ra< 0.4µm and the possibility of electropolishing for the most sensitive applications.

The mechanical design takes into account the operating pressure and temperature of fermenters, heat exchangers and sterilisation systems, while guaranteeing effective cleaning, easier access for maintenance and maximum installation safety.

OUR CUSTOM SKID

solutions

ZIEMEX fermentation skids can be fitted with all the equipment required to control the process. The products can be sterilised on line before they are put into the fermenter, while automatic cleaning in place (CIP) ensures perfect hygiene and simplified maintenance.

ZIEMEX fermenters are designed to guarantee maximum sterility with surface conditions up to Ra < 0.6µm, optimum homogenisation that can be simulated by CFD (Computational Fluid Dynamics) if necessary, and effective heat transfer through the addition of more internal surfaces if that is required by the process.

The skid assembly can also include our economisers to optimise energy consumption and the most efficient Z-compact® heat exchangers to reduce heat loss and allow precise control of temperature throughout the fermentation process.

The solutions are adapted both for conventional methods and for demanding processes that call for sterile conditions, homogeneous circulation and perfect control over fermentation kinetics.

Example of use

FERMENTATION SKID FOR PHARMACEUTICALS: PROCESS CONTROL, ENERGY EFFICIENCY AND COMPLIANCE

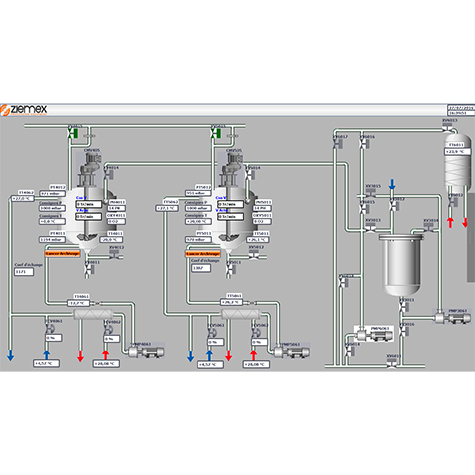

For a major player in the pharma industry, ZIEMEX designed and manufactured a fermentation skid containing two 30m³ fermenters.

The installation comprised an on-line sterilisation system for products and automated cleaning in place (CIP) to guarantee process hygiene and safety.

ZIEMEX fermenters made it possible to achieve optimum homogenisation and efficient heat transfer, with additional internal surfaces to meet the specific needs of the process.

Z-compact® heat exchangers and economisers guaranteed high energy efficiency while reducing the consumption of steam and utilities. Complete fermentation control, material traceability and strict compliance with pharmaceuticals standards were the watchwords of this project carried out by the ZIEMEX teams, from design to commissioning.

Do you want to put in place a fermentation skid?

ZIEMEX can adapt to your processes, reactions and cleaning and layout requirements. Our technical staff work along with your quality, production or validation teams to ensure fast and compliant commissioning.