Home > Zieplate welded plate heat exchangers

Zieplate welded plate heat exchangers

optimised thermal performance for low pinch values

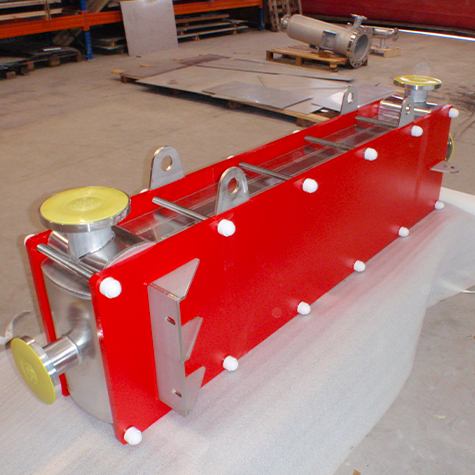

Zieplate welded plate heat exchangers combine the thermal efficiency of plates with a design optimised for applications that require perfect counterflow heat exchange.

Their innovative design eliminates thermal and mechanical stresses and guarantees exceptional reliability, even in demanding cyclical processes.

With their rectangular design and flexible flat bottom, Zieplate exchangers provide maximum performance even with small temperature differences. They are suitable for all types of fluid, clean or slightly fouling, and can include chemical or mechanical cleaning solutions for easy and regular maintenance.

Zieplate

SOLUTIONS

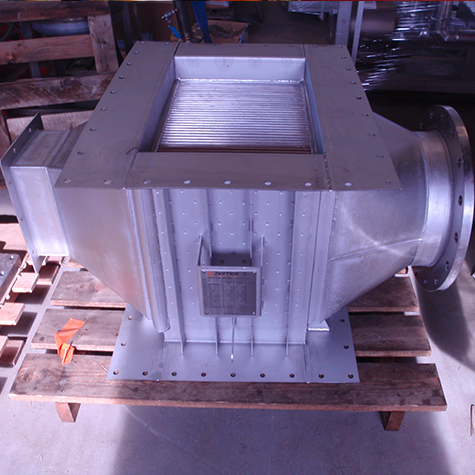

Zieplate heat exchangers offer improved thermal performance thanks to an optimised exchange surface and a perfect counterflow configuration.

This design maximises efficiency while reducing the space taken up in your plant.

Mechanical reliability is guaranteed by collection at the ends of the bundle and a flexible flat bottom design, limiting stresses and risks of leaks. The reduced number of welds and absence of points of contact between plates extend the equipment’s useful life and minimise fouling.

Allowing full inspection and cleaning, Zieplate exchangers can be fitted with doors on both sides for full access. A cleaning nozzle allows for effective cleaning without full disassembly, thus guaranteeing simplified maintenance and consistent performance.

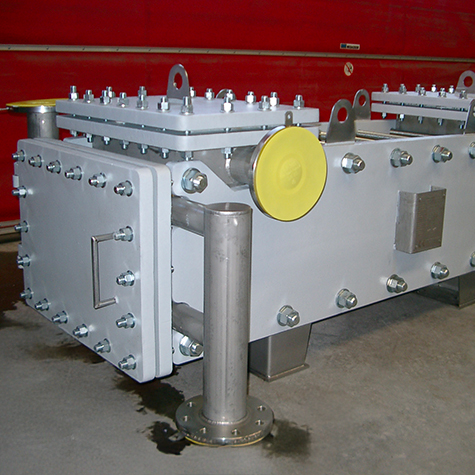

Each heat exchanger is custom designed to fully adapt to your layout, process and maintenance requirements. The installation can directly replace an existing piece of equipment without modifying the piping, and the compact design makes it easy to incorporate it into a process line, reducing costs and mechanical stresses.

For such projects, ZIEMEX mobilises its expert teams in engineering, metallurgy, processes , and its integrated manufacturing factory.

TECHNICAL SPECIFICATIONS

to boost your performance

We make Zieplate heat exchangers in the material best suited to your process. That may be standard stainless steel such as 304L or 316L, corrosion-resistant stainless steel such as 904L or 310L, duplex, super duplex, titanium, Hastelloy® C22, C276 or C2000, Inconel® or zirconium.

The permissible temperature ranges extend from -200°C to +200°C, thus covering cryogenic processes and moderate-temperature applications alike. ZIEMEX Zieplate exchangers are sized for operating in absolute vacuum (-1 barg) and can withstand pressures up to 30 barg.

EXAMPLE

of use

As part of a project for an industrial laundry, ZIEMEX designed a Zieplate welded plate heat exchanger to meet a regulatory requirement under which the temperature of the waste water discharged after passing through a water treatment plant needed to be below 30°C.

The installation was designed to operate based on several scenarios, but sizing was based on the most restrictive of them: cooling the water, charged with textile fibres, at 40°C to bring it below the regulatory limit before discharge. The heat recovered was used to preheat the clean water to be used by the process, from 25°C to above 35°C.

- Wastewater circuit: temperature reduction from 40°C to below 30°C, with intentionally wide plate spacing to minimize fouling risk and prevent fiber accumulation.

- Circuit eau propre : élévation de la température de 25 °C à plus de 35 °C, atteignant un pincement thermique très faible et maximisant la récupération énergétique.

To make maintenance easier, the equipment was fitted with doors on the process side to allow direct access to the inside for complete cleaning of the circuit. This configuration enabled the customer to comply with regulations, reduce energy needs and achieve quick return on investment, with also ensuring reliable, inspectable and sustainable equipment.