Home > Processing equipment > Custom industrial heat exchangers > Z-compact® welded plate heat exchangers

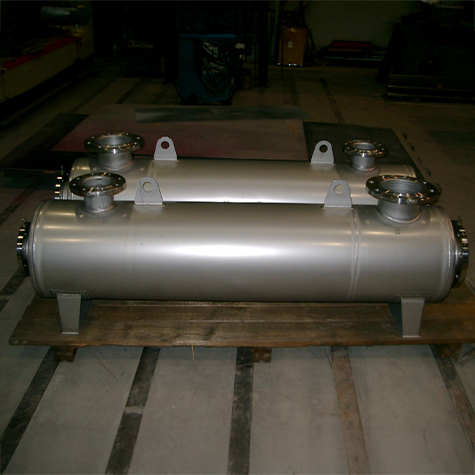

Z-compact® welded plate heat exchangers

Thermal performance and mechanical robustness

Z-compact® welded plate heat exchangers combine the thermal performance of plate heat exchangers with the mechanical strength of shell & tube heat exchangers.

Their unique design, within a cylindrical shell, eliminates stresses due to differential thermal expansion to guarantee exceptional reliability, even under extreme pressure, temperature or thermal shock conditions.

A heat exchanger offering high thermal performance and mechanical strength.

Thanks to their compact design, they offer an optimised exchange surface while taking up little space. Z-compact® exchangers are entirely custom designed, and can fulfil all thermal functions: condenser, evaporator (including under vacuum), heater, cooler or thermosiphon.

They are suitable for clean fluids and also for highly fouling products, with integrated chemical or mechanical cleaning solutions.

Z-compact®

SOLUTIONS

Z-compact® welded plate heat exchangers achieve thermal performance superior to that of conventional shell & tube heat exchangers thanks to their optimised exchange surface and lower head loss.

That heightened performance makes them the ideal solution to maximise efficiency while reducing the space taken up in your facility.

Their mechanical reliability is strengthened by proven design which can use U chambers welded at only one end. This principle enables the plates to dilate freely and does away with stresses due to differential thermal dilatation. This feature is essential for withstanding thermal shocks and repeated operating cycles, thus extending the life of the equipment.

Z-compact® exchangers have been designed to make inspection and maintenance easier, as they allow full inspection and cleaning using chemical or mechanical methods. ZIEMEX has developed a special cleaning nozzle that allows effective cleaning without full disassembly, thus guaranteeing simplified maintenance and consistent performance.

Full adaptability forms an integral part of their design. Each heat exchanger is custom designed to correspond to your layout, process and maintenance requirements. They can be installed to replace existing equipment directly, without modifying the piping, and may include two bundles of plates in a single shell to create a two-in-one condenser, which can, for instance, first cool with temperate water and then allow maximum condensation with low-temperature glycol.

Lastly, their compact design makes them easy to incorporate directly into a process line, reducing installation costs and limiting mechanical stresses. The ZIEMEX performance guarantee is based on a precise thermal, hydraulic and mechanical design that is validated by expert calculations compliant with international standards, for reliable and sustainable service in the most demanding operating conditions.

For such projects, ZIEMEX mobilises its expert teams in engineering, metallurgy, processes, and its integrated manufacturing factory.

TECHNICAL SPECIFICATIONS

to boost your performance

We make Z-compact® heat exchangers in the material best suited to your process. That may be standard stainless steel such as 304L or 316L, corrosion-resistant stainless steel such as 904L or 310L, duplex, titanium, Hastelloy® C22, C276 or C2000, Inconel® or zirconium.

The permissible temperature ranges are wide. We manufacture exchangers in which liquid nitrogen can circulate at -200°C, or for gaseous processes at very high temperatures rising up to 1,150°C.

ZIEMEX Z-compact® heat exchangers are regularly sized for operating in absolute vacuum and can withstand pressures up to 200 barg.

BENEFITS OF Z-COMPACT

for our fine chemicals customer

Working for a customer in the chemicals industry, ZIEMEX designed different Z-compact® welded plate heat exchangers capable of handling a variety of process operating scenarios, one of which is particularly demanding: methanol gas condensation at -10°C in a 30 mbar vacuum.

The equipment has a single shell with two distinct bundles of plates made in Hastelloy® C22 to withstand the highly corrosive process:

- Main bundle: cooling of methanol gases using cold water at 11°C, condensing the majority of the vapors.

- Post-condenser: further reduction of residual gas temperature down to -10°C using a 50% MEG circulation at -15°C, to condense the final non-condensables and optimize overall efficiency.

For complete cleaning of the two circuits, the equipment was designed with three flanges: one body flange and two plain flanges, providing direct access to both sides of the exchanger.

That two-in-one configuration enabled the customer to optimise energy efficiency, reduce space requirements and avoid a large number of pieces of equipment and piping.

A prime example of how Z-compact® fully meets the needs of space constraints and extreme thermal conditions, while making maintenance simpler.

Do you have a project ?

Let’s discuss your dimensional constraints, processes, and layout.

Our engineers support you from design to installation.