ZIEMEX has been providing expertise in the most demanding of industries since 1957.

Specialising in the design and manufacture of thermal and chemical engineering equipment, the company has been able to combine industrial tradition and cutting-edge technology, gaining recognition both in France and abroad.

Our success has always relied on a consistent quality and process control requirements and the pursuit of high-performance solutions.

From breweries to chemicals, and from pharmacy to the oil industry, at ZIEMEX, we have been able to adapt our know-how to developments in these markets while maintaining an unchanging philosophy: build durably, with precision and reliability.

Key stages

in our development

Creation of Ziemann France, specialists in the manufacture of equipment for the food and chemical industries.

The company gains instant recognition for its high-quality stainless steel production and precision manufacturing processes

Ziemann France joins the Ziemann Group (D), world leader in turnkey brewery construction.

This union marks the start of major international growth and structuring of “turnkey brewery” projects.

Introduction of explosive forming for manufacturing large pillow plate for heat exchange, an innovative technology at the time.

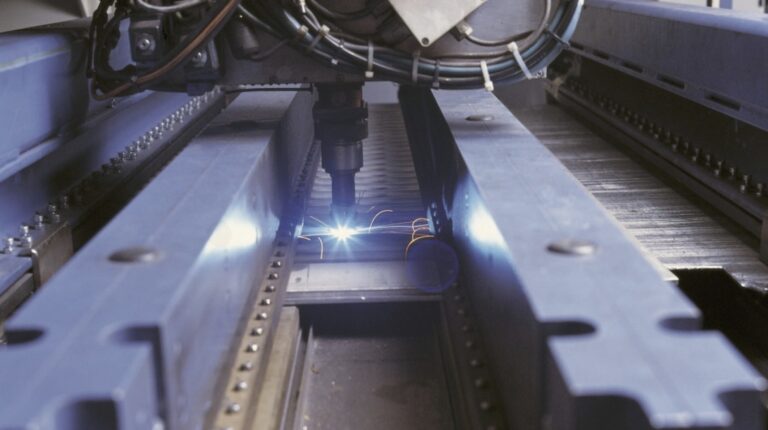

Industrialisation of laser welding for pillow plates, guaranteeing enhanced thermal performance and exceptional durability.

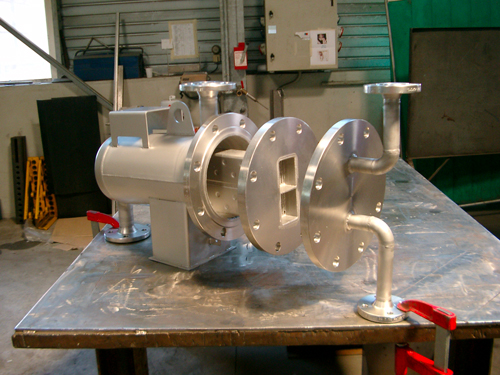

Ziemann France and Packinox join to create the subsidiary Ziepack, specialising in high-performance welded plate exchangers.

This union marks a key stage in mastering large-scale heat exchange technology.

Ziemann designs and manufactures their first proprietary designs for welded plate exchangers, heralding the future Zcompact® range, a symbol of innovation and compactness.

Following an LBO (Leveraged Buy-Out), Ziemann France becomes ZIEMEX SAS.

This transformation marks the founding of an independent entity, based in France and focusing on highly technical projects.

A second LBO begins a new phase for ZIEMEX SAS, with industrial development, investment in production facilities and consolidation abroad.

Installation of 132 photovoltaic panels at the Sarre-Union site, representing 6% of its annual energy consumption and an estimated 4-tonne reduction in CO₂ per year.

This initiative illustrates ZIEMEX's desire to make greater progress towards an ambitious CSR and environmental approach.

ZIEMEX continues to develop in the green chemicals industry, biotechnology and pharmaceutical processes by investing in R&D, digital simulation and special materials.

The company continues to exemplify French industrial excellence, combining performance, durability and innovation while maintaining our position as a supplier of industrial fermentation sub-assemblies.

Solid industrial integration

and a committed team

Established at a 16,500m² site in Sarre-Union, ZIEMEX encompasses all the necessary expertise for the design and manufacture of processing equipment:

- a Design Office focused on mechanical and thermal calculations and design,

- a production facility with expertise in welding, assembly and testing,

- on-site teams overseeing installation and commissioning, both in France and abroad.

ZIEMEX currently employs more than 140 people — engineers, technicians, welders, apprentices — united in pursuit of one goal: delivering high-performance, safe and durable equipment.

Let’s write the next chapter together!

Do you have an industrial equipment project or idea to develop, or a specific custom design need? Our teams of engineers and technicians are on hand to support you at every stage, from research to commissioning, anywhere in the world.

ZIEMEX, your partner for the most stringent processes.