Home > Our global solutions > Custom industrial sterilisation

Custom industrial sterilisation

Health and safety, regulatory compliance and energy optimisation

Sterilisation is a key stage in a number of industrial processes, particularly food processing, biotechnology, pharmaceuticals and fine chemicals.

It consists in raising the temperature of a product to a set level over a set amount of time, and then keeping it at that temperature in order to eliminate or inactivate micro-organisms.

At ZIEMEX, we design and produce thermal solutions which guarantee health and safety, as well as regulatory compliance and energy optimisation, and which also perfectly integrate into production lines.

INDUSTRIAL STERILISATION

Definition and requirements

Industrial sterilisation is based on three major thermal stages:

- Rapid heating to the set sterilisation temperature.

- Maintaining the product at this temperature for a certain time.

- Controlled cooling to prepare the product for the next stage (packaging, fermentation, storage, etc.).

The challenges vary depending on the sector:

Food processing: guaranteeing microbiological safety without altering organoleptic qualities.

Pharmaceuticals and biotech: ensuring compliance with strict GMPs (good manufacturing practices) standards, traceability and preserving the effectiveness of sensitive molecules.

Fine chemicals: sterilising or conditioning intermediary flows in highly regulated environments.

ZIEMEX TECHNOLOGY AND

KNOW-HOW

At ZIEMEX, we provide integrated thermal solutions tailored for sterilisation:

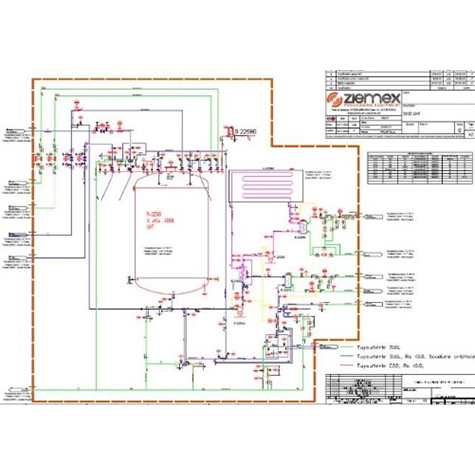

- Heating and maintenance with Z-compact® heat exchangers: cycle consistency and efficiency.

- Sterilisation holding tanks: controlled residence time to guarantee uniform destruction of micro-organisms.

- Custom coolers: fast, safe temperature reduction.

- Integration of economisers: heat recovery from the steriliser product for preheating input → significant reduction in vapour consumption.

Our solutions are designed to easily integrate into production lines, and to ensure cleaning in place (CIP), guaranteeing hygiene and ease of use.

BENEFITS

for your processes

ZIEMEX sterilisation solutions provide significant advantages:

- Controlled sanitary safety: reliable elimination of microorganisms.

- Preserved product quality: precise thermal cycles tailored to each application.

- Energy efficiency: heat recovery and utilization, with reduced energy consumption.

- Regulatory compliance: adherence to food, pharmaceutical, and biotech industry standards.

- Ease of operation: seamless integration into existing lines, with simplified operation through automation.

ASSOCIATED

services

ZIEMEX supports its customers throughout the life cycle of their equipment and processes:

Custom preliminary design and design

Integration of process, thermal and mechanical requirements from the quotation stage. The studies take into account the need for concentration, decarbonising and energy efficiency.

Factory design and manufacturing

3D design using Inventor, mechanical and thermal calculations, PIDs, definition of equipment and monitoring of manufacturing. Compliance with design codes (ASME, CODAP, EN 13445, AD 2000) and the PED.

Testing and validation

Factory Acceptance Test (FAT) at our production facilities and Site Acceptance Test (SAT) at the customer’s site. Process validation and adjustment of parameters before entry into production.

R&D and pilot station

Possibility to test the process on our test station: fermentation, distillation, evaporation, crystallisation etc. These tests validate the thermal balance and product behaviour before transfer to the industrial scale.

Maintenance and long-term monitoring

Technical support, periodic inspection, thermal or mechanical audit, adaptation of equipment to process changes.

Get in touch with our teams

Industrial sterilisation is a complex balance between microbiological safety, respect for product quality and energy optimisation. ZIEMEX’s skills in heat transfer and hygienic design have established us as a leading partner for your sterilisation processes. Get in touch with our experts to design a solution tailored to your needs.