Home > Processing equipment > Custom industrial heat exchangers > Ziepack® welded plate heat exchangers

Ziepack® welded plate heat exchangers

compact size and maximum thermal efficiency

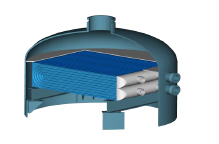

Ziepack® plate heat exchangers are designed to pack exceptional thermal performance in an optimally compact and lightweight unit.

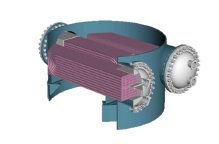

Developed in collaboration with our subsidiary Ziepack, a joint venture of ZIEMEX and Alfa Laval Packinox, these exchangers use laser welding technology of the tube/tube type, assembled in bundles.

This approach makes it possible to reach exchange surfaces up to 16,000m² and 140 tonnes, guaranteeing superior thermal performance even in complex and demanding industrial applications.

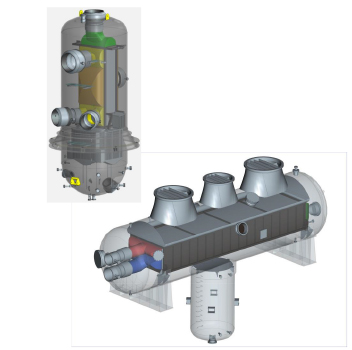

Thanks to their compact design, Ziepack® exchangers can be integrated directly into column heads or shells, thus reducing mechanical stresses and optimising available space. They are suitable for a large range of fluids and can be adapted to applications requiring vacuum condensers, economisers or other special thermal functions.

Ziepack®

solutions

Ziepack® heat exchangers offer maximum thermal efficiency with reduced head loss, making them particularly suitable for installations where space is at a premium but where performance remains critical.

Tube/tube laser welding allows exceptional precision and joint quality, giving the equipment robustness, reliability and a long life.

To make inspection and maintenance easier, manholes may be incorporated into the collecting pipes of Ziepack® bundles, providing quick and safe access to the plates for visual inspection or partial cleaning.

Adaptability is the main rationale of the Ziepack® design. Each heat exchanger is sized for its purpose, to correspond to the specific requirements of the process and all installation constraints. With its compact size and light weight, it can be incorporated directly into column heads or in shells, limiting the number of pieces of equipment required and reducing installation and maintenance costs.

- Vacuum condensers at column heads

- Reboilers

- Shell exchangers

- Energy economisers

The ZIEMEX performance guarantee is based on a thermal, hydraulic and mechanical design that is specific to the customer and validated by accurate and tested calculations, for reliable and sustainable service in all operating conditions.

Technical specifications

to serve your performance

We make Ziepack® heat exchangers in the material best suited to your process. That may be standard stainless steel such as 304L or 316L, corrosion-resistant stainless steel such as 904L or 310L, duplex, super duplex, titanium, Hastelloy® C22, C276 or C2000, Inconel® or zirconium.

The permissible temperature ranges extend from -200°C to +200°C, thus covering cryogenic processes and moderate-temperature applications alike.

ZIEMEX Ziepack® exchangers are regularly sized for operating in absolute vacuum (-1 barg) and can withstand pressures up to 30 barg.

Example

of use

For a petrochemicals company, ZIEMEX designed a vacuum condenser for phenol exposed to corrosive agents. The water flow rate required for condensing phenol with crossflow and 2 passes (out/back in the plates) meant that the rate had to be high, yet head loss had to be minimised.

Tube/tube laser welding technology was perfectly suited to address those requirements: it can withstand very high design pressures and makes it possible to limit head loss to accept high flow rates.

The exchanger was made in 904L with 0.8 mm thick plates to offer optimum resistance to corrosion while maintaining maximum thermal performance. The design also allows inspection and maintenance, with manholes integrated into the collecting pipes, facilitating inspection and cleaning without full disassembly.

This solution enabled the customer to optimise energy efficiency, take up less space and limit the number of pieces of equipment and piping, while meeting the stringent requirements for compactness, thermal performance and resistance to corrosion.

Do you have a project?

Talk to us about your dimensional, process and layout requirements.

Our engineers are on hand to support you from design to installation.