Home > Ziebloc™ welded plate heat exchangers

Ziebloc™ welded plate heat exchangers

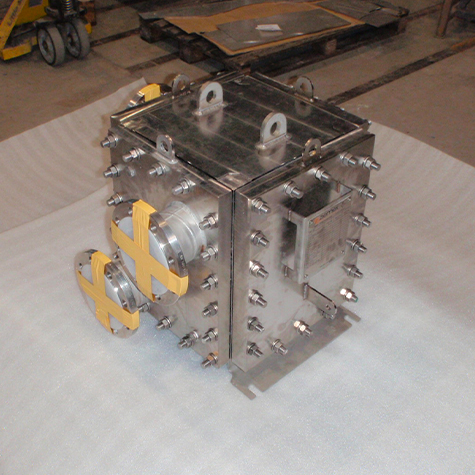

Ultra-compact and fully cleanable

Ziebloc™ welded plate heat exchangers combine exceptional compactness with a design developed for applications that require full access for cleaning and simplified maintenance.

Thanks to their absolutely smooth modular exchange surface, they minimise fouling risks while offering high thermal performance, even in the most constrained environments.

Designed to bring together thermal efficiency and ease of maintenance, Ziebloc™ offer an optimised exchange surface, with no point of contact between plates.

That unique design prevents particles from being retained and reduces dead zones, thus guaranteeing perfect hygiene and reliable operation over the long term. Their compactness makes them ideal for sites where space is limited, while offering the possibility of direct mechanical cleaning thanks to complete access inside the circuits.

Ziebloc™

solutions

Ziebloc™ heat exchangers offer:

- superior thermal performance thanks to a modular exchange surface, optimised to maximise exchange coefficients while at the same time reducing space requirements,

- heightened reliability with plate spacing that can be above 20 mm to minimise the risk of fouling, including with loaded fluids,

- low product retention thanks to a fully drainable design which limits thermal inertia and optimises each production cycle,

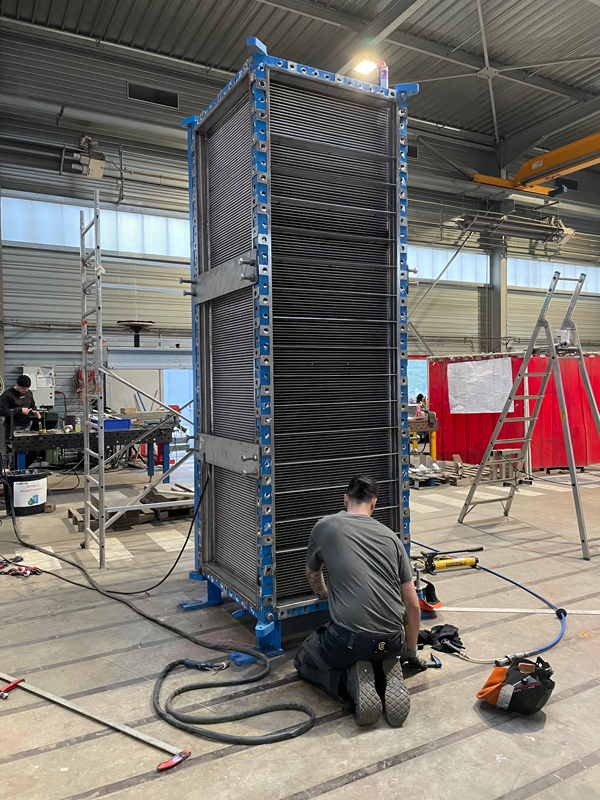

- easy maintenance via four doors (two per circuit) giving direct visual access to the whole exchange surface for quick cleaning and inspection,

- total adaptability thanks to custom manufacturing which allows incorporation without modifying the piping, both in new installations and to replace existing equipment,

- and a compact modular design with a painted steel or stainless steel frame adapted to all industrial configurations.

Technical specifications

to boost your performance

We make Ziebloc™ heat exchangers in the material best suited to your process. That may be standard stainless steel such as 304L or 316L, corrosion-resistant stainless steel such as 904L or 310L, duplex, super duplex, titanium, Hastelloy® C22, C276 or C2000, Inconel® or zirconium.

The permissible temperature ranges extend from -200°C to +200°C, thus covering cryogenic processes and moderate-temperature applications alike.

ZIEMEX Ziebloc™ exchangers are sized for operating in absolute vacuum (-1 barg) and can withstand pressures up to 30 barg.

Example

of use

For an industrial plant, ZIEMEX designed a Ziebloc™ welded plate heat exchanger to recover energy from particularly hot and fouling effluent.

The customer wanted to lower the temperature of loaded waste water exiting at 146°C before it was discharged into the natural environment, while using the heat to heat its production plant.

The Ziebloc® exchanger made it possible to transfer that energy to spring water and raise its temperature from 15°C to 137°C, and then use it to heat the building. The solution enabled the customer to do away with the use of steam, thus significantly reducing the site’s energy costs and overall consumption.

The heat exchanger is designed to operate with fouling fluids, and has 8 mm spacing on each circuit and custom internal baffles to keep the circulation speed high and thus significantly limit deposits.

Summer maintenance is simplified by four removable doors, which offer direct access inside the equipment for complete inspection and cleaning. Thanks to the ZIEMEX solution, the customer was able to reduce heat emissions, optimise energy efficiency and extend the life of the installation while ensuring reliable and sustainable operation.