Home > Processing equipment > TOD, CCT and BBT fermentation tank for breweries > TOD, CCT and BBT fermentation tanks

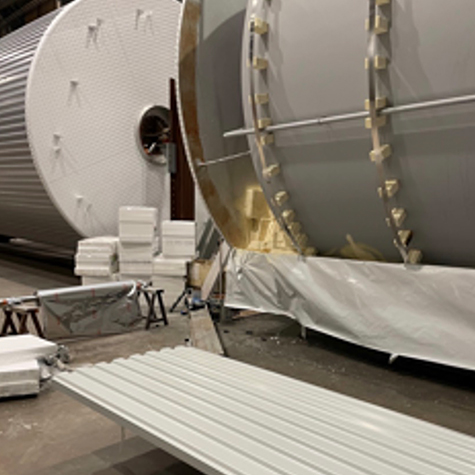

BBT & TBF storage tanks

designed for beer clarity and stability

In the final stage before bottling, storage in a BBT (Bright Beer Tank) or TBF (Finished Beer Tank) enables the beer to be clarified and stabilised at a low temperature.

At ZIEMEX, we design and manufacture custom tanks which guarantee ideal storage conditions, impeccable hygiene and optimal thermal regulation.

Our BBTs are manufactured in food-grade stainless steel, with pickled, passivated and polished finishes, ensuring that they are perfectly sanitary and visually exemplary.

They include all the necessary accessories for processing control and operator safety.

Customised

sizing

BBT tanks differ from TOD/CCT fermenters in terms of both their geometry and operation. With no settling cone, they are designed to withstand a higher internal pressure in order to keep the beer pressurised until it is bottled.

At ZIEMEX, we size each tank in accordance with:

- The useful volume and rate of production,

- The pressure and temperature requirements,

- The installation conditions (internal or external),

- The requirements for integration with the bottling lines.

High-performance insulation limits temperature rises, guaranteeing perfectly stabilised beer and extended storage without any alteration in its organoleptic qualities.

Hygiene &

safety

In the final stage before packaging, the storage tank must be as clean as a fermenter. At ZIEMEX, we use the same design standards to ensure the tank is perfectly hygienic and fully cleaned by CIP systems.

The equipment may include static spray balls, rotating spray heads and targeted nozzles for specific areas.

The internal surface finishes (Ra ≤ 0.8µm, _option for 0.6µm upon request_) guarantee optimum cleanability and the absence of residue retention. The absence of active yeast makes cleaning quicker, while still ensuring a maximum level of hygiene before bottling.

In terms of safety, ZIEMEX designs include anti-overpressure and anti-vacuum valves, calibrated valves, and level, temperature and pressure control accessories.

These devices protect the tank from pressure variations linked to washing cycles (50°C and higher) or rapid cooling, preventing any deformation and guaranteeing safe, durable operation.

Cooling

or temperature maintenance

During the storage phase, once the fermentation process is finished, the priority is to keep the beer at a low temperature to preserve its clarity and prevent the yeast from reactivating.

At ZIEMEX, we provide two levels of temperature control, designed to meet the needs of each brewery:

- Standard injected polyurethane foam insulation, sufficient for most environments.

- Active cooling with our laser welded single embossed pillow plates, identical to those used in TOD fermenters, for precise temperature maintenance, even in hot or exposed environments.

This design enables precise temperature control, while also limiting energy consumption and thermal variations in the product.

Finishing &

integration within the Brewery

Each BBT tank is produced with the same care as our fermenters:

- external insulation, polished or riveted, depending on the required design,

- configured connections depending on your instruments,

- integration of valves, sensors, sampling taps and level columns,

- preparation for hoisting, installation and connection on site.

At ZIEMEX, we are also able to manage the full installation — walkways, ladders, connections — providing a turnkey solution that is perfectly integrated into your production line.

Designed for craft breweries and industrial breweries alike, our tanks guarantee the stability and EBC colour of your beer, right through to the final stage in the process.

Get in touch with our teams to design your custom storage tank.

Talk to us about your dimensional, process and layout requirements.

Our engineers are on hand to support you from design to installation.