Home > Processing equipment > TOD, CCT and BBT fermentation tank for breweries

TOD, CCT and BBT fermentation tanks

Complete beer tanks for breweries

With 60+ years’ experience designing equipment for breweries, we design and manufacture custom TOD and BBT fermentation tanks at ZIEMEX which meet the different production requirements for all types of beer.

Our custom TOD/CCT fermentation tanks and BBT/TBF storage tanks meet all the requirements for breweries:

- manufactured in food-grade stainless steel

- low roughness, with surface finishes designed for impeccable hygiene

- cooling performance

- accessories and components that optimise fermentation cycles and make them safe

Each tank can be fully defined and integrated in terms of its dimensions, and it can also be provided with specific insulation and control accessories which enable fermentation monitoring and equipment maintenance.

Our tanks are designed to guarantee:

- Impeccable hygiene for each CIP cleaning cycle, with a surface finish roughness of up to < 0.6µm,

- Quick cooling, with fibre CNC laser welded cooling pillows which allow glycol water to circulate evenly,

- Low temperature maintained with 150 mm injected polyurethane foam cold insulation, which also contributes to energy saving,

- Safe operation with pressure-regulating accessories a complete range

a complete range

for all your beer production stages

At ZIEMEX, we design and manufacture different types of tank for breweries, to be used for beer production as well as water storage, cooling water, yeast storage and spent grain storage:

TOD and CCT

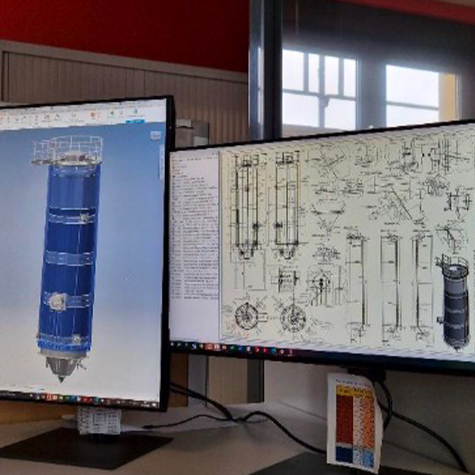

At ZIEMEX, we design and manufacture custom TOD and CCT fermentation tanks; essential equipment for the process of transforming wort into beer.

These tanks promote yeast separation and ensure rapid cleaning between each mash. Manufactured in cold-rolled stainless steel, they have a surface finish of less than 0.8 µm, injected polyurethane insulation, and laser-welded cooling pillows for optimal thermal performance. They can also be adapted for other uses such as distilling.

BBT and TBF

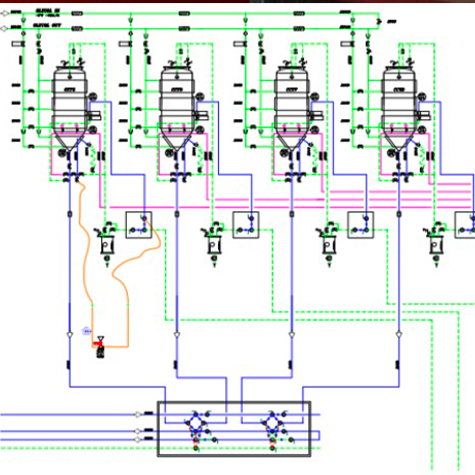

After fermentation, the beer is transferred to the cold storage tanks for clarification and storage before bottling.

These BBT and TBF tanks keep the beer at a low temperature, under optimal hygiene conditions.

They have built-in devices for safety, control and CIP cleaning which ensure that the process is perfectly sterile.

Yeast production equipment

At ZIEMEX, we help manage your yeasts with yeast propagator tanks for use in your TODs. Our tanks can be provided with agitators, temperature control, and a control box for controlling the agitator, valves and CIP washing cycle.

These can all be delivered assembled.

Water tanks

Thanks to our experience in manufacturing processing tanks, we can adapt our tanks to meet brewers’ needs: water storage, low temperature glycol water tank, pressurised storage, hot water recovery to minimise energy loss.

Our know-how enables the insulation and stainless steel used to be adapted to suit each scenario, and the fluid circulation to be optimised with customised fittings.

Spent grain silo

For storage of by-products and reuse of waste

Green waste from the wort is stored and sold as a by-product, generally for animal feed.

Our tanks can be supplied with all the accessories for filling, storage and drainage of spent grain, thus enabling waste to be re-used most effectively.

Business case

TOD & CCT: a comprehensive solution

A recognised brewer in Savoie asked us to produce several TOD fermentation tanks and BBT storage tanks. More generally, they also entrusted us with:

- control of the logistics, delivery and integration within the brewery

- installation of safety accessories and walkways

- addition of custom walkways at the correct height for maintenance

- integration of sensors and replacement of information in the tank supervision room

- provision of tank piping and bypass assembly

This meant the customer had a contractor partner managing the project as a whole, instead of going through multiple integrators which can lead to coordination and costing problems.

Thanks to our precise management of the project, from initial design study through to manufacturing and installation, our customer did not need to concern themselves with coordination requirements, particularly in the final logistics approach phase, allowing for fast and flawless integration into the brewery and the adjoining taproom.

It was essential to work at a fast pace on site and ensure visual integration in order to satisfy our customer and their consumers, who visit the taproom to taste their different beers.

Advantages for the customer

- Savings in research and looking for suppliers

- Technical integration to optimise management of TOD fermenters

- Transfer of responsibility or logistics to an overall partner who supervises the final unloading and hoisting at the work site

- Visual integration within the brewery, for local interest and promotion

For your brewery projects

ZIEMEX can support you from the very early stages of your plans up to commissioning of compliant, sustainable and efficient equipment.