Home > Processing equipment > Custom industrial heat exchangers > Single embossed pillow plate

Single embossed pillow plate

Many industrial processes require efficient heat transfer. Single embossed pillow plates represent a particularly high-performance solution.

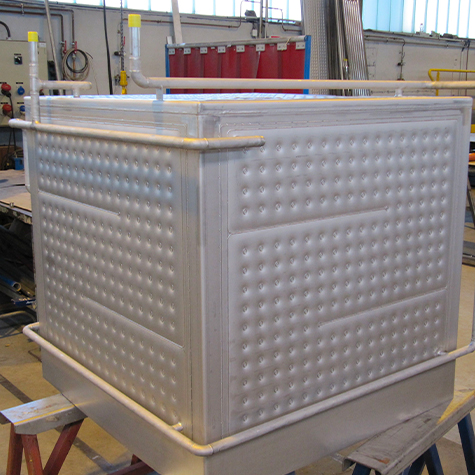

They ensure that products in a tank or processing chamber are heated or cooled with a high degree of reliability.

At ZIEMEX, we calculate exchange surfaces, spacing between welding areas and other dimensional parameters in-house, depending on the application. With more than 30 years’ experience in heat transfer, we guarantee both the mechanical robustness and thermal performance of our solutions.

Single embossed

pillow plate solutions

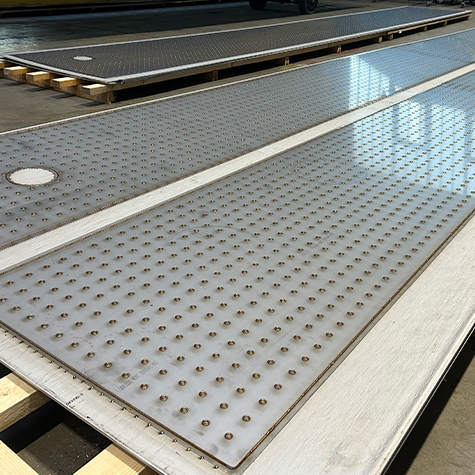

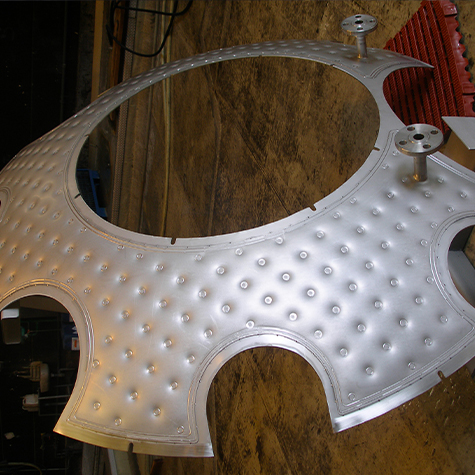

The principle of the single embossed pillow plate relies on the assembly of a fine sheet (0.8 to 2 mm) which is welded onto a thicker sheet (3 to 20 mm). Once inflated, only the thin sheet deforms, creating circulation channels for the utility fluid (vapour, hot water, glycol water, thermal oil, liquid nitrogen, Freon, CO₂, etc.).

This design produces a strong convection effect within the pillow plate and, through conduction, effective heat transfer to the process taking place in the tank or chamber.

In addition, due to the laser weld points distributed across the entire surface, the pressure of the utility fluid is not part of the tank’s mechanical calculation. This guarantees optimal performance, even under demanding service conditions.

Single embossed pillow plates are currently used for:

- Processing tanks,

- Fermenters,

- Reactors,

- Cryogenic screens

- Panel heaters

Technical specifications

to boost your performance

We design single embossed pillow plates in the most suitable material for your application, whether that be standard stainless steel such as 304L or 316L, high alloy, corrosion-resistant stainless steel such as 904L or 310L, duplex or super duplex, titanium, Hastelloy® C22, C276 or C2000, Inconel® or zirconium.

The permissible temperature ranges extend from -200°C to +200°C, covering cryogenic processes and moderate heating applications alike.

Our pillow plates are frequently sized to operate under and withstand service pressures of up to 15 barg, with hydraulic tests carried out up to 23 barg.

Thanks to our expertise in digitally controlled laser welding, we guarantee excellent mechanical performance when exposed to thermal cycles and pressure spikes, ensuring a high degree of thermal flexibility and a uniform temperature gradient.

Example

of use

We designed a fermenter that was 5 metres in diameter and 16 metres in length for a customer in the chemicals industry, to perform standard heating and cooling cycles.

The single embossed pillow plate, including the lower 12 mm-thick layer, guaranteed thermal regulation. This enabled vapour to be circulated at 6 barg to quickly heat the process from 30°C to 121°C, then a cooling circuit with 50% MEG was used to bring the temperature down from 121°C to 30°C as quickly as possible.

The assembly was designed to keep the load lost from the pillow plate below 1.5 barg, while adhering to the calculation requirements in terms of pressure and temperature.

In order to cope with the significant exothermicity generated during the sterilisation phase, requiring the discharge of almost 3000 kW, we added an internal coil to complete the solution. This customisation enables perfect temperature control to be guaranteed, illustrating ZIEMEX’s ability to design custom solutions which are adapted to meet the specific needs of each process.

Do you have a project?

Talk to us about your dimensional, process and layout requirements.

Our engineers are on hand to support you from design to installation.