Home > Processing equipment > Turnkey process skid > Custom sterilisation skids

Custom sterilisation skids

Energy efficiency, reliability and compliance

Sterilisation is a key stage in a number of industrial processes, particularly food processing, biotechnology, pharmaceuticals and fine chemicals. It consists in raising the temperature of a product to a set level over a set amount of time, and then keeping it at that temperature in order to eliminate or inactivate micro-organisms.

ZIEMEX sterilisation skids are custom designed to address the most stringent health and regulatory requirements, while guaranteeing energy efficiency, high reliability and smooth incorporation into production lines.

TECHNICAL SPECIFICATIONS

of sterilisation skids

IEMEX sterilisation skids cover a wide range of temperatures, from 70°C (for example, for enzyme lysis) to 150°C for applications calling for strict sterilisation. Each piece of equipment is designed to be easy to clean in place and meet the most demanding health standards.

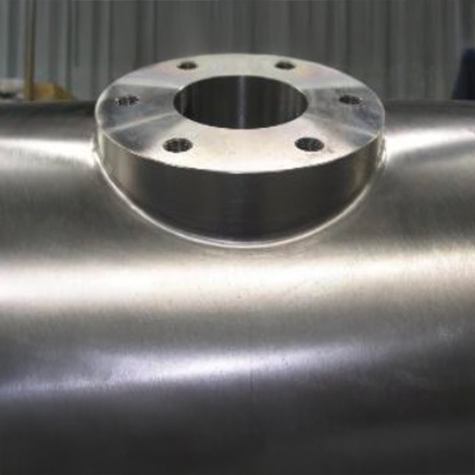

Surface conditions are guaranteed at Ra < 0.8µm, with the possibility of dropping to Ra < 0.4µm or applying electropolishing for the most sensitive applications. These finishes limit deposits, make cleaning easier and improve the durability of equipment.

The materials used can vary depending on the process requirements: 304L, 316L stainless steel or high-alloy steels for more corrosive environments. Instrumentation and automation systems are also incorporated to measure, allowing close control of temperatures, holding time and cleaning cycles.

OUR STERILISATION

solutions

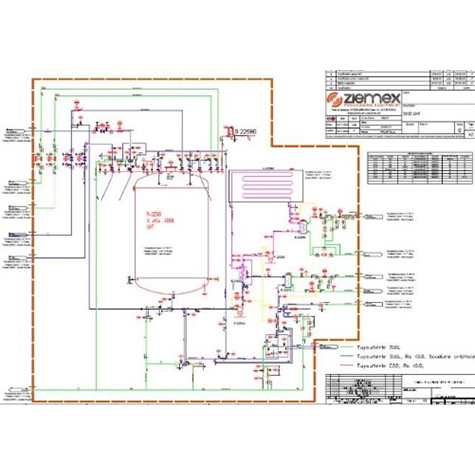

A ZIEMEX sterilisation skid includes several thermal stages for the complete and homogeneous treatment of the product.

The product is first rapidly heated to the sterilisation temperature using a heater. Then it passes into a ZIEMEX holder, which holds it at precisely that temperature for the required time. Lastly, a final cooler brings the product down to the appropriate temperature for remainder of the process or packaging.

To optimise energy consumption, an economiser is incorporated in order to recover heat from the sterilised product to preheat the incoming product. This type of equipment is specially designed to ensure perfectly homogeneous fluid speeds over the whole exchange surface, to avoid stagnation zones and to ensure sterilisation is complete and regular.

It is also designed to allow automated cleaning in place (CIP), guaranteeing impeccable hygiene and great operating simplicity.

Example of use

STERILISATION SKIDS WITH Z-COMPACT® ECONOMISER: HIGH ENERGY EFFICIENCY AND PHARMACEUTICALS COMPLIANCE

For a major player in fine chemicals, ZIEMEX designed and made two separate skids to meet specific needs:

- A sterilisation skid that takes the product to 140°C and holds it there for 30 seconds, with a flow rate of 30 m³/h.

- A lysis skid designed to process product at 85°C for 5 minutes, also with a flow rate of 30 m³/h.

The installation included a high-performance Z-compact® economiser to heat the incoming product up to 115°C using the heat recovered from the product already sterilised at 140°C. Only the additional calories were supplied by the steam, considerably reducing the energy consumption of the process.

High energy performance, controlled concentration, material traceability and strict compliance with pharmaceuticals standards were the watchwords of this project carried out by the ZIEMEX teams, from design to commissioning.

Looking for the best sterilisation skid solution?

ZIEMEX can adapt to your processes, reactions and cleaning and layout requirements. Our technical staff work along with your quality, production or validation teams to ensure fast and compliant commissioning.