Home > Processing equipment > Turnkey process skid > Custom skids – Designed and made by ZIEMEX

Custom skids – Designed and made by ZIEMEX

to guarantee performance

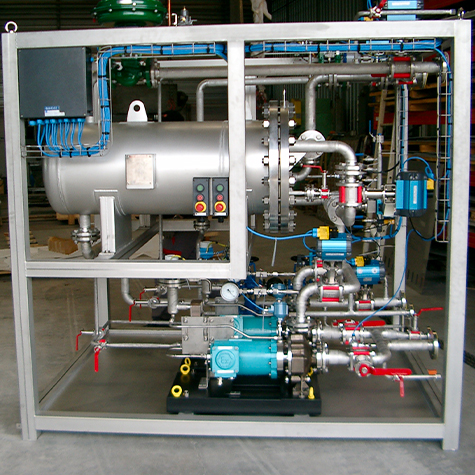

ZIEMEX custom process skids are fully personalised solutions designed to meet specific needs in all types of industrial process.

Whether for temperature regulation, filtration, chemical reactions, distillation, gas treatment or energy management, or teams make turnkey skids that incorporate all the features required.

All these skids are designed for optimised compactness, easy cleaning and reliable operation. Components and instruments (valves, pumps, sensors) can be standardised or adapted to ensure compatibility with the customer’s stock and flexibility to adjust the process as production changes.

Each skid is sized, assembled and tested to ensure high performance, safety and reliability, while simplifying installation and maintenance on the site.

CUSTOM SKIDS

Technical specifications

ZIEMEX custom skids are entirely personalised to meet the customer’s requirements.

A wide range of materials can be used, from conventional stainless steel such as 304L or 316L, high-alloy steels, titanium, Hastelloy® or zirconium.

The equipment is designed to withstand definite pressures and temperatures, at the same time optimising heat transfer, fluid homogenisation and ease of cleaning. Surface conditions can be guaranteed up to Ra < 0.4µm and electropolished finishes can help limit deposits and maximise sterility and the life of the equipment.

The incorporation of automation and instrumentation is customised for precise control over critical parameters and safe and simple operation.

OUR CUSTOM SKID

solutions

Our various skids can incorporate a large variety of components, depending on the specific needs of each customer. They can include reactors, filters, distillation columns, exchangers, condensers, concentrators and much more. Each function is adapted for the specific process: for example, temperature regulation can be achieved with different fluids (liquid nitrogen, MEG, water, steam, electrical heating) with ranges from -90°C to +350°C and accuracy up to ±1°C.

- Filtration skids enable the processing of products at controlled temperatures while maintaining consistent quality.

- Reaction skids or micro-reactors integrate thermal regulation of reactors or crystallizers, as well as distillation, decantation, or condensation, depending on process requirements.

- Gas treatment skids can include condensation and product storage with controlled defrosting.

- Energy management skids for thermal or solar energy storage and production.

Example of use

CUSTOM INSTALLATION OF A SKID FOR A CHEMICALS MANUFACTURER

For a customer in the chemicals industry, ZIEMEX supplied a full package turnkey project: a reactor on which we welded single embossed pillow plates and an associated temperature regulation skid.

The 50% MEG glycol loop of the skid can precisely heat or cool the reactor. This loop is heated via a Z-compact heater supplied with steam at 6 barg, then cooled by two Z-compact coolers.

The first uses temperate water at 7°C, before it is lowered further to -20°C via a second 50% MEG exchanger. The skid can handle all the reactor cycles, with regulation designed to save energy.

The functional analysis was carried out in house, with FAT of the complete operation of the equipment and finalised SAT commissioning on-site.

This approach guarantees an efficient, flexible and totally reliable installation for the customer.

Do you want to put in place a custom process skid?

ZIEMEX can adapt to your processes, reactions and cleaning and layout requirements. Our technical staff work along with your quality, production or validation teams to ensure fast and compliant commissioning.