Home > Processing equipment > Turnkey process skid > Custom evaporation and concentration skids

Custom evaporation and concentration skids

Efficiency and precision

Evaporation and concentration is a process that increases the concentration of a solution by separating part of the solvent by evaporation and then condensing it.

This process is widely used in the chemicals, pharmaceuticals, food processing and environmental industries to reduce the volumes to process, re-use by-products or reach a certain concentration before a crystallisation or formulation stage.

ZIEMEX evaporation and concentration skids are custom designed for incorporation into customers’ processes, while guaranteeing energy performance, flexibility and reliability.

EVAPORATION AND CONCENTRATION

solutions

The principle of evaporation and concentration relies on the separation of solvent from a solution to increase concentration. This separation can be achieved in three main ways:

- Firstly, the thermosiphon method uses the natural circulation created by the difference in density between the heated liquid and the vapour generated, displacing the fluid with no additional pump, with effective heat transfer.

- After that, evaporation may be followed by a flash process in a vessel, where the pressure is reduced suddenly. Such pressure reduction instantaneously evaporates part of the solvent with no change in the temperature of the fluid, as the temperature remains above the boiling temperature for the new pressure. The liquid-vapour mixture is then separated in the tank: the vapour phase can be condensed and the liquid phase, which is more concentrated, is collected for the downstream process.

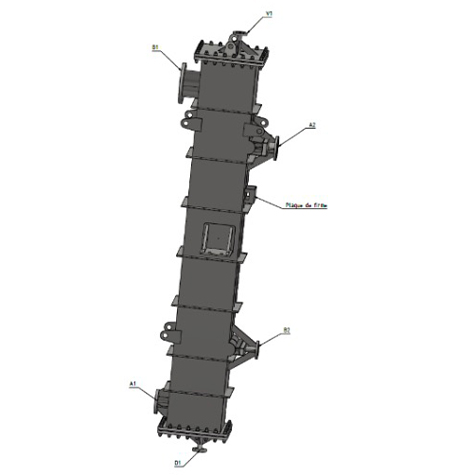

- Lastly, the falling film evaporation method consists in spreading the liquid in a fine film along the plates of a heat exchanger, thus optimising heat exchange, limiting the risks of retention and allowing easier cleaning.

To carry out these stages, ZIEMEX incorporates its own Z-Compact® or Zieplate heat exchangers directly at the foot of the column. These solutions are compact in size and offer high evaporation performance to meet the most demanding requirements of industrial processes.

TECHNICAL

SPECIFICATIONS

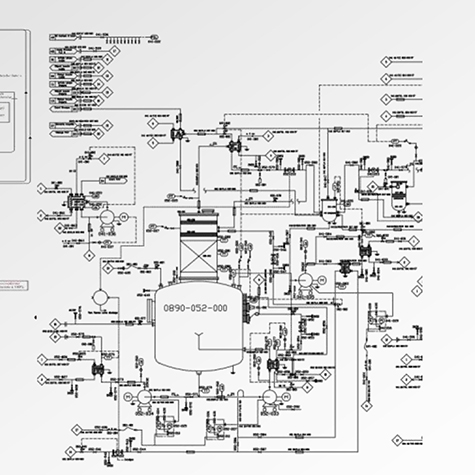

ZIEMEX evaporation and concentration skids are entirely personalised to meet the needs of each customer. They can be made in a wide range of materials depending on process requirements, ranging from conventional stainless steel such as 304L or 316L to high-alloy materials such as duplex, super duplex, titanium Hastelloy® or zirconium.

The design is based on definite pressure and temperature values, at the same time optimising head loss and ease of cleaning. We can also make equipment that meets surface roughness requirements, with finishes up to Ra < 0.4µm.

The whole skid is designed to be compact, easy to incorporate into the customer’s environment and provide robustness over time, guaranteeing both reliability and safety.

Example of use

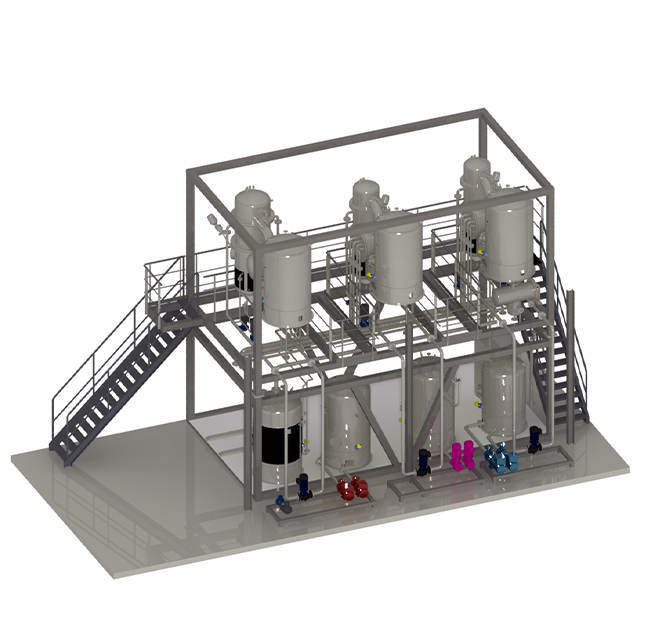

Z-COMPACT THERMOSIPHON EVAPORATION AND CONCENTRATION SKID: HIGH PERFORMANCE AND COMPACT SIZE

For a chemicals manufacturer, ZIEMEX designed an evaporation and concentration skid with a Z-compact evaporator at the foot of the column, with thermosiphon operation.

This choice made it possible to achieve excellent thermal performance, at the same time reducing size and doing away with the need for a recirculation pump.

The vapour phase from the flash vessel was condensed in a specially designed ZIEMEX heat exchanger, while the concentrated liquid was directly reinjected in the following process stage.

Because of its significant size, the skid was designed in the form of four blocks, 4 metres high by 4 metres wide and long, in order to facilitate transport up to the customer’s site.

In spite of the modular design, the assembly was fully mounted during the factory acceptance test (FAT) in our facilities to ensure smooth operation before shipment.

Do you want to put in place an evaporation and concentration skid?

ZIEMEX can adapt to your processes, reactions and cleaning and layout requirements. Our technical staff work along with your quality, production or validation teams to ensure fast and compliant commissioning.