Home > Processing equipment > Turnkey process skid > Custom distillation skids

Custom distillation skids

High energy efficiency and optimum integration

Distillation is a separation process which uses the volatility differences between the constituents of a liquid mixture.

Successive heating and condensation results in separate, purified fractions, whether solvents, monomers, pharmaceuticals or chemicals with high added value.

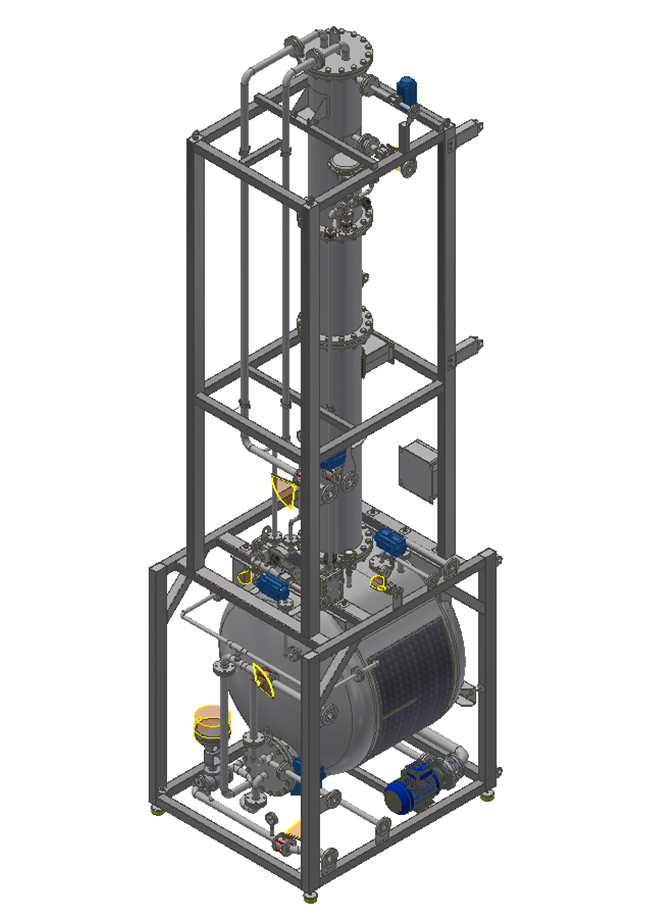

ZIEMEX distillation skids are custom designed to guarantee perfect control over purity, high energy efficiency and optimised integration into your industrial processes.

distillation skids

Technical specifications

ZIEMEX distillation skids are entirely personalised to meet the specific requirements of each process.

They can be made in a wide range of materials ranging from standard stainless steels such as 304L and 316L to high-alloy steels such as duplex, super duplex, titanium, Hastelloy® or zirconium.

Surface conditions are controlled, with finishes up to Ra < 0.4µm, and the possibility of electropolishing for pharmaceuticals applications or the most sensitive processes.

The mechanical design takes into account the operating pressures and temperatures, head loss and ease of cleaning, while guaranteeing the robustness and safety of the equipment.

Our distillation

solutions

ZIEMEX distillation skids can operate under high vacuum conditions, up to 20 mbar absolute, or under high pressure, beyond 100 bars, and cover a wide range of temperatures ranging from cryogenic processes up to 500°C.

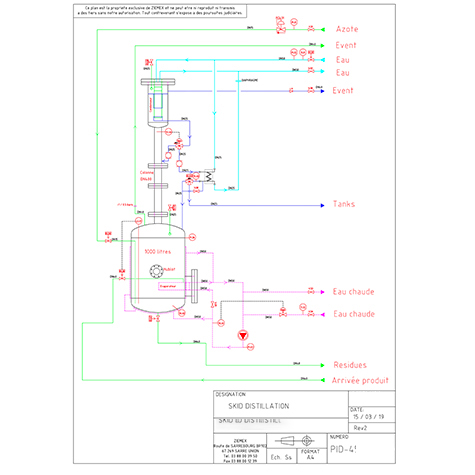

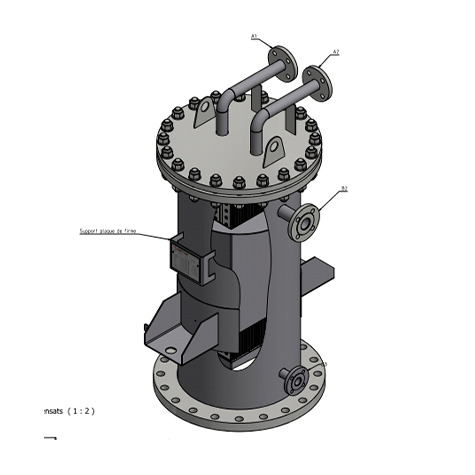

The columns are used along with Z-compact® or Zieplate heat exchangers, which heat and cool the flows, and are adapted to the utilities available on the site. Condensers with several temperature levels help optimise energy consumption while reducing discharge. Depending on the process, heat pumps or mechanical vapour recompression systems can be included to further drive down vapour consumption and the carbon footprint of the process.

The skids are designed to handle clean fluids as well as loaded or fouling fluids and offer high performance in a small space, with no retention and easier cleaning.

Example of use

High-precision distillation skid

For a major fine chemicals company, ZIEMEX designed and manufactured a high-precision distillation skid for producing ultra-pure solvents such as methanol, THF, acetonitrile, IPA, hexane and dichloromethane with a flow rate of 1,000 litres/hour.

The installation included factory-produced columns with their internals, Z-compact® heat exchangers for heating and cooling, condensers with several temperature levels in order to reduce energy consumption while optimising solvent recovery.

High energy performance, controlled purity, material traceability and strict compliance with pharmaceuticals standards were the watchwords of this project carried out by the ZIEMEX teams, from design to commissioning.

Do you want to put in place a distillation skid?

ZIEMEX can adapt to your processes, reactions and cleaning and layout requirements. Our technical staff work along with your quality, production or validation teams to ensure fast and compliant commissioning.