Home > Processing equipment > Turnkey process skid

Turnkey process skid

Custom designing for turnkey installations

In the food processing, pharmaceuticals, chemicals and energy industries, manufacturing processes require reliable, high-performance equipment that complies with the most stringent standards.

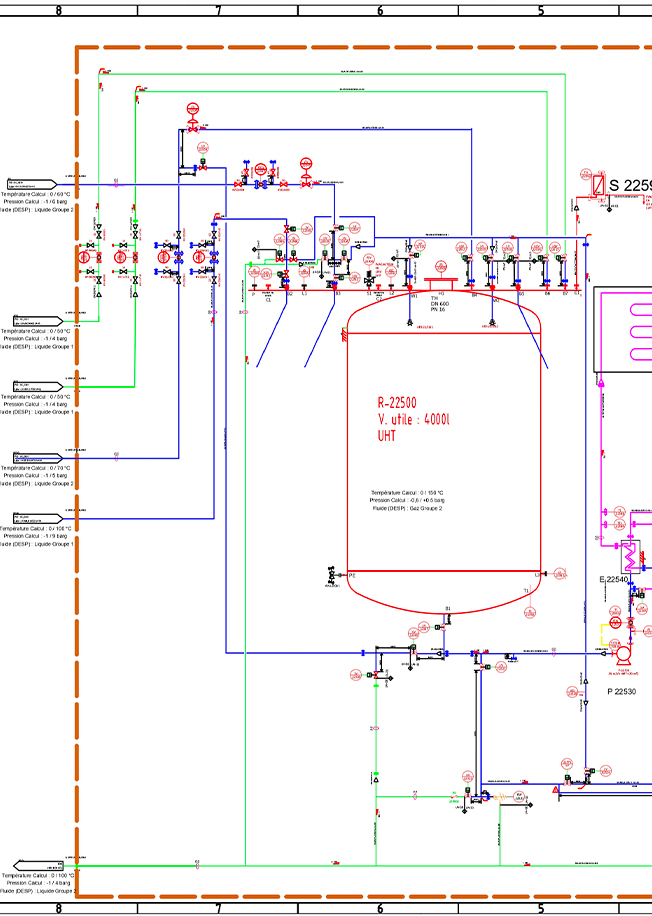

ZIEMEX process skids offer a turnkey solution that incorporates all the equipment required for your process within the same compact structure:

- heat exchangers,

- pumps and valves,

- instrumentation and control systems.

Our skids are designed and manufactured in our production facilities in France to guarantee performance, safety and compliance with regulations, while reducing both the time taken for commissioning and the risks relating to multiple interfaces.

Each skid is entirely sized to suit your thermal, mechanical and process needs, with full traceability and factory tests before delivery.

Our expertise in skid design:

- Integrated thermal and mechanical engineering to guarantee precise sizing tailored to the process.

- Factory prefabrication of compact and modular skids to limit the risk of errors and cut installation time.

- Regulatory compliance (PED, FDA, GMP, CODAP, ASME, EN-13445) and compliance with the most stringent hygiene requirements.

- Full support with FAT (Factory Acceptance Test), SAT (Site Acceptance Test) and training of operators for smooth start-up.

Equipment integration and

standardisation

ZIEMEX skids can directly incorporate our own thermal equipment: heat exchangers (operating as condensers, evaporators, heaters or coolers), as well as reactors and fermenters, connected to the skid’s thermal loop for precise heating or cooling.

Instrumentation and components (pumps, valves, sensors etc.) can be standardised based on the customer’s choice of parts, to guarantee:

- perfect compatibility with existing stock,

- greater flexibility to adapt production to market developments,

- lower operating costs thanks to the use of standard components that are easily replaceable.

Benefits of our process skids

designed for your manufacturing requirements

Turnkey solution

A single technical interface, which simplifies project management and the supply chain.

Time saving

Assembly, wiring, tests and validation completed before shipment.

Maximum reliability

Standardised components, easy maintenance and perfect compatibility between all elements.

Flexibility

Modular design for speedy adaptation to production changes.

Safety and compliance

Compliance with the most stringent hygiene, quality and industrial safety standards.

our

process SKID solutions

Each industrial process has its specific constraints _(temperature, pressure, type of fluid, hygiene requirements, available space)_. Which is why ZIEMEX designs process skids that are made to specifications and adapted to your needs:

Evaporation and concentration skid

Designed to concentrate products using vacuum or atmospheric evaporation, the evaporation and concentration skid includes an evaporator, condenser, pumps and instrumentation.

Ideal for food processing (juice, syrup, extracts), chemicals or pharmaceuticals, it helps optimise energy consumption and guarantee consistent product quality.

Sterilisation skid

Designed for heat treating food products or pharmaceuticals, sterilisation skids allow precise and even heating in accordance with the most demanding hygiene requirements (FDA, GMP).

They are compact and automated to guarantee the safety, repeatability and traceability of cycles.

Distillation skid

These skids include distillation columns, condensers, boilers and instrumentation, to separate constituents by volatility.

Distillation skids are suitable for the chemicals, pharmaceuticals and food processing industries, offering high operating precision with fine regulation and optimised energy efficiency.

Fermentation skid

Designed for biotechnology and fermentation, brewery, yeast, bio-gas, pharmaceuticals, these skids include reactors, temperature regulation systems, agitation, gas injection and automated control.

Fermentation skids create a stable process environment, which is reproducible and in compliance with health standards.

Custom skid

ZIEMEX also develops specific skids to address particular needs: heating/cooling systems, CIP (cleaning in place), injection skids, pilot units or test beds.

Each solution can be customised entirely to adapt to your process, with a compact, reliable and open-ended design.

Do you have a project

for a process skid?

ZIEMEX can support you from the very early stages of your plans up to commissioning of compliant, sustainable and efficient equipment.