Home > Processing equipment > TOD, CCT and BBT fermentation tank for breweries > Yeast tanks to control your yeast

Yeast tanks

Designed to control your yeast

Yeast tanks in brewing: the key role of yeast

Yeast is the living material that turns wort into beer. By metabolising the sugar, it produces alcohol, the flavours and some of the carbon dioxide gas characteristic of each recipe.

For the process to be regular and controlled, yeast must be prepared in ideally suitable conditions before it is added to fermenters.

Depending on the type of beer, different yeast species are used:

- Saccharomyces cerevisiae for top-fermented beer,

- Saccharomyces pastorianus for bottom-fermented beer.

Each of these requires a specific preparation protocol: temperature, oxygenation, agitation and purity must be controlled.

That is the function of the yeast tank, an invaluable tool when it comes to controlling the biology of the brewing process.

Role of

the yeast tank

A well-designed yeast tank guarantees a quick and regular start to fermentation, with consistent flavouring between brews.

A yeast tank is not a fermenter: it is a propagating tank where the yeast multiplies and becomes stronger before it is used.

It carries out three essential functions:

- Adequate biomass production: a suitable volume of viable cells to effectively seed the fermenters without weakening the original strain.

- Physiological conditioning: the yeast tank creates a nutritive and oxygen-rich environment in which the yeast can build up its energy reserves before withstanding the more challenging conditions in the fermenter (alcohol, CO₂, pressure, low temperature).

- Microbiological safety: designed to operate in aseptic environments, it prevents bacterial or fungal contamination that could affect the taste or stability of the beer.

Benefits

of a ZIEMEX yeast tank

Thanks to their custom design and complete instrumentation, ZIEMEX yeast tanks provide:

- rapid initiation of fermentation,

- perfect repeatability of flavour profiles,

- consistent quality between batches,

- sound and stable yeast culture.

Our yeast tanks are robust, hygienic and easy to operate, and can be incorporated seamlessly into your existing plant, adapting to your production volumes and protocols.

Design

of the yeast tank

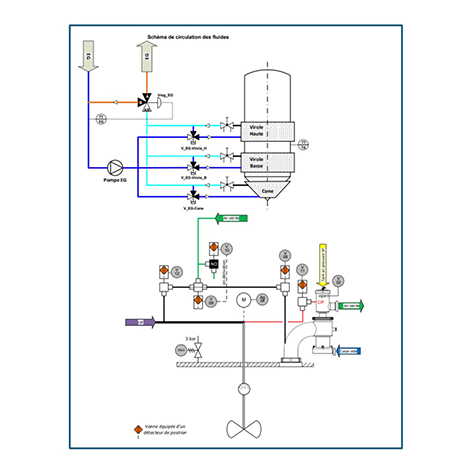

ZIEMEX designs efficient and fully instrumented yeast tanks that ensure the even and controlled growth of yeast in a controlled environment.

Our designs are based on the following key principles:

- Controlled air or oxygen: precisely controlled aeration to stimulate cell multiplication and strengthen the membranes of the yeast.

- Power-operated agitator: for consistent homogenisation and even distribution of oxygen and nutrients.

- Precise temperature regulation: our laser-welded single embossed pillow plates allow the temperature to be regulated closely, a key factor in keeping the yeast in its optimum growth zone (warmer for ales, cooler for lagers).

- Automated CIP cleaning: for full disinfection between two cultures to prevent cross contamination between strains and biofilm development.

During the growth phase, the brewer can monitor different parameters: pH, viability, cell density, temperature, agitation, weight. These data make it possible to adjust the cycle in real time and make sure that the yeast is ready for use.

Instrumentation and

centralised control

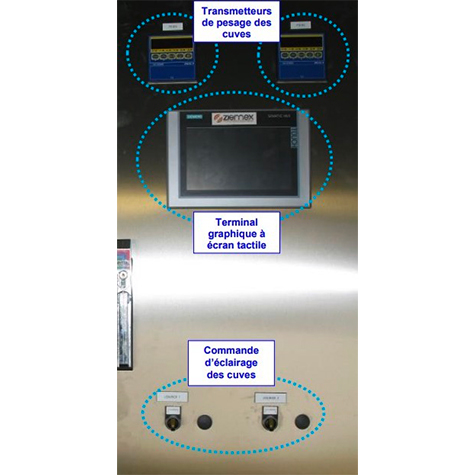

ZIEMEX supplies complete yeast tanks, delivered with all their accessories, sensors and the regulation systems required:

- valves for supply and oxygenation,

- probes measuring the temperature, pressure and level,

- integrated weighing system,

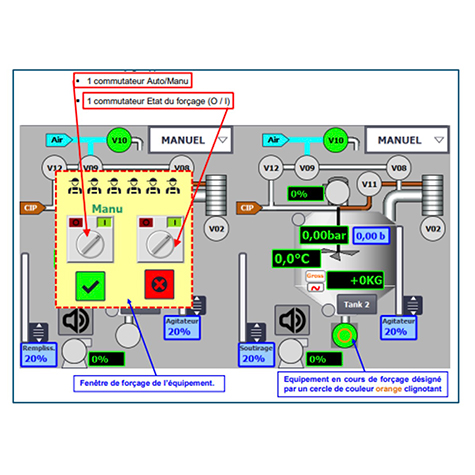

- main control cabinet with touch screen for general supervision.

All process information is grouped and centralised for simple and intuitive control, allowing the brewer to fully master the yeast culture.

Tell us about your projects!

Talk to us about your dimensional, process and layout requirements.

Our engineers are on hand to support you from design to installation.