Home > Processing equipment > THERMIPACK® – Modular tower for solvent condensation, decanting and storage

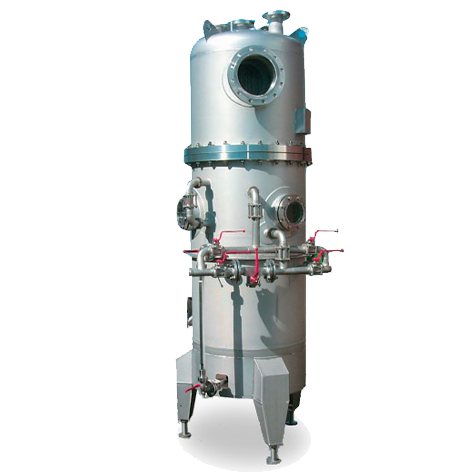

THERMIPACK® – Modular tower for solvent condensation, decanting and storage

Compact modular tower for pharmaceutical and chemical processes

THERMIPACK® is an innovative solution developed by ZIEMEX to optimise thermal management and handling of solvents in pharmaceutical, chemical and biotechnological processes.

It takes the form of a compact modular tower, combining the functions of solvent condensation, decanting and storage in a single unit.

Designed to comply with the most demanding installation requirements, THERMIPACK® requires up to four times less space than a conventional installation.

Its modular design enables certain modules (such as the decanter) to be added or removed depending on the needs of the process or the evolution of the unit.

THERMIPACK®

Our solution for optimisation of thermal management and solvent handling

This technology is particularly useful where an installation is being extended or modernised, where there is limited space, or where a reduction in solvent loss and VOC emissions is a major environmental and economic issue.

In addition to being compact, THERMIPACK® has been designed for fast, safe cleaning, with a design which can be fully emptied, with no dead zones, and with smooth surfaces and fixed washing nozzles which enable CIP cleaning, in accordance with FDA (Food and Drug Administration) and GMP (Good Manufacturing Practice) requirements.

INTEGRATED SOLUTIONS WITH THE ZIEMEX

THERMIPACK®

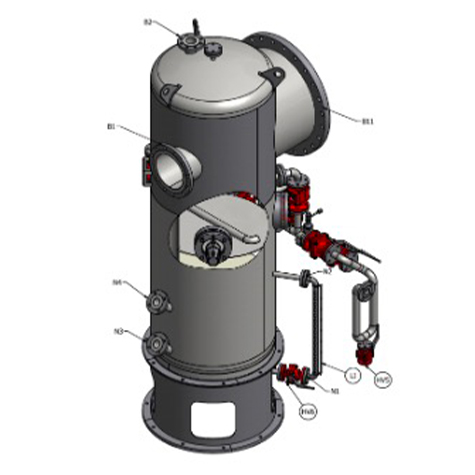

THERMIPACK® brings together all the key stages of solvent management and treatment in a single, modular tower:

- Two-stage condensation, ensuring optimal thermal efficiency and a significant reduction in VOC emissions.

- Decantation, integrated as needed, for effective liquid phase separation.

- Secure solvent storage, reducing handling and enabling on-site analysis or pre-treatment.

Its modular design enables certain modules to be added or removed during the useful life of the installation.

This flexibility makes it an ideal solution both for new projects and for retrofitting existing units. The choice of materials is fully customisable: stainless steel, Hastelloy, Iconel or Zirconium, depending on the nature of the fluids, the chemical and thermal requirements, and the regulatory requirements.

INDUSTRIAL APPLICATIONS OF THERMIPACK®

- Pharmaceutical industry: solvent recovery and purification, vapor condensation, sterile storage.

- Fine chemistry: processes requiring high condensation efficiency and strict emission control.

- Biotechnology: sterile processes, frequent cleaning cycles, compliance with FDA and GMP standards.

- Facility modernization: replacement of bulky equipment with a compact, integrated unit.

TECHNICAL

& economic advantages

The THERMIPACK® is not just about saving space. It provides a series of advantages that directly improve the performance and effectiveness of processes:

Unparalleled compactness

Occupies up to 4 times less floor space than a traditional installation.

Reduced piping

Up to 80% fewer connections, reducing costs, heat loss and risk of leakage.

Less handling

Integrated storage, analyses and pre-treatments on site.

Simplified cleaning

Smooth surfaces, no dead zones, complete emptying, fixed nozzles, all without disassembly.

Environmental performance

Significant reduction in VOCs due to two-stage condensation.

CUSTOMER CASE:

Optimisation of an aggressive pharmaceutical process

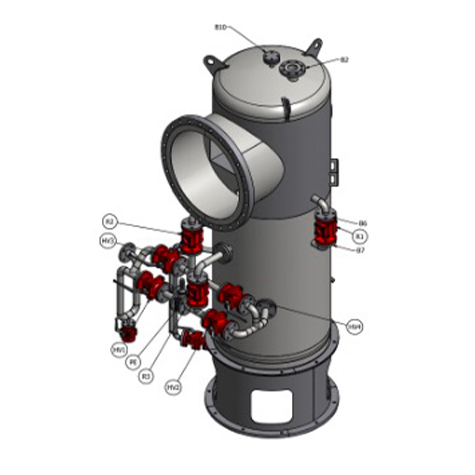

At ZIEMEX, we designed and manufactured several THERMIPACK® for an international pharmaceutical group. They were specifically customised for a particularly aggressive, corrosive process.

In order to guarantee maximum resistance, the units were produced in C22, C2000 and C276 alloys (Hastelloy®) – materials recognised for their exceptional performance in extreme chemical environments.

The use of THERMIPACK® enabled the customer to significantly reduce the length and number of Hastelloy® pipes used. An expensive material, this generated important savings on the initial investment.

Another major requirement related to the available surface area, given that the chosen technical premises was particularly cramped. Due to its unparalleled compactness, THERMIPACK® was able to be integrated with no structural modification to the buildings, combining condensation, decanting and storage in a single unit.

At ZIEMEX, we also guarantee the maintenance and replacement of condensation bodies. These are considered wear parts when they are subjected to a very demanding process. Our team is able to replace them in just a few weeks, thus guaranteeing production continuity and limiting costly stoppages.

Do you have a project?

Need to optimise your processes with a compact, high-performance solution? Get in touch with our teams to design your custom THERMIPACK®.