Home > Processing equipment > Custom industrial reactors > Single embossed pillow plate reactors

Single embossed pillow plate reactors

Optimum heat regulation for your demanding manufacturing processes.

Choose the ZIEMEX solution for you repeated thermal cycles

The small welded surface and low thickness make the assembly more capable of withstanding thermal shocks. These surfaces are fabricated using high-performance CNC machines capable of laser welding.

From the thermal point of view, the single embossed pillow plate solution also provides greater efficiency.

The temperature gradient between the medium and the product is greater. Exchange is thus more efficient, with the same quantity of fluid. Homogeneity is also improved.

All the welding spot points contribute to the exchange, like a welded plate heat exchanger, by creating undulations that create turbulence conducive to exchange.

The Reynolds number is thus higher with this solution.

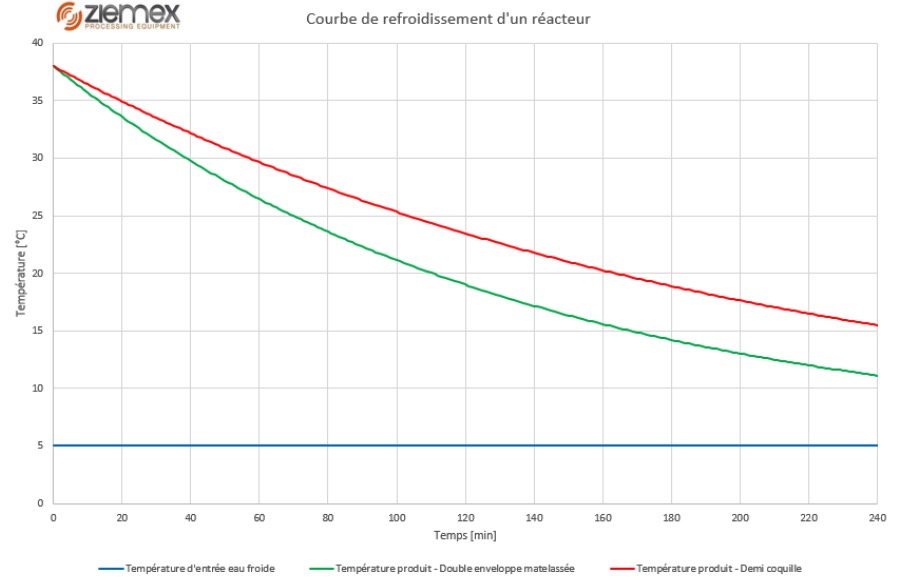

Comparisons in our use case demonstrate the gains provided by our plates for heating or cooling a reactor.

Our 30 years’ experience in laser welding, combined with feedback received on the ground and our control over heat exchange guarantee a fully adapted solution to boost the thermal performance of your process.

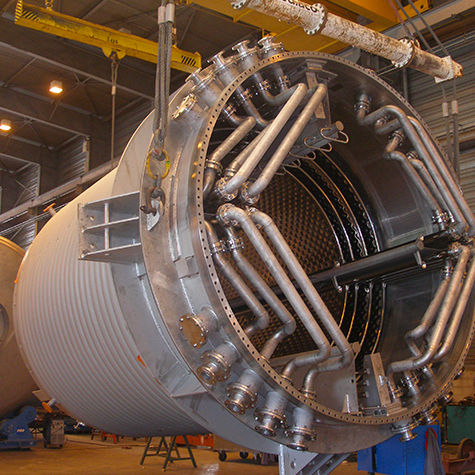

REACTORS WITH INTERNAL EXCHANGE SURFACE

to maximise the exchange surface and handle extreme energy transfers.

When the exchange surface available on the shell and bottom of the reactor is insufficient, an additional internal surface can be added.

This can be achieved by an immersed coil or the proven ZIEMEX solution: immersed plate coils or panels, which allow close control over the reaction, as well as cleaning and regulation.

ZIEMEX uses proven manufacturing procedures to guarantee optimum finishing:

- Final internal roughness < 0.6µm even for large volumes,

- Polishing and welding of agitators in the workshop, following a specific assembly procedure,

- Assembly of sub-assemblies in a controlled environment

- Systematic quality control (visual, dimensional, metallurgical, Ra, etc.).

FOR ALL YOUR ENVIRONMENTS,

however critical

These pieces of equipment meet the most stringent safety and environmental standards:

- GMP, ATEX, PED 2014/68/EU, ASME compliance

- Can be integrated into sterile zones or clean rooms,

- Complete traceability and technical documentation supplied with the equipment.

HALF COILS VS SINGLE EMBOSSED PILLOW PLATES:

what is the difference?

In industry, two broad solutions are used to heat or cool tanks and reactors: half coils and single embossed pillow plates.

Although they both achieve the goal of heat transfer, their design and performance differ substantially.

Half coils are half cylinders that are welded directly to the wall of the tank. The utility fluid circulates in that limited space.

While it may be a robust and easy-to-implement solution, it does have some drawbacks:

- Limited exchange surface, since the fluid only circulates in the areas covered by the half coils.

- Increased space requirement, due to the additional thickness added to the tank.

- Less flexibility in respect of thermal cycles or rapid temperature variations.

The quilted double jacket consists of a thin sheet metal laser-welded to the tank wall. Once inflated, circulation channels are created, through which the utility fluid (steam, glycol water, thermal oil, liquid nitrogen, etc.) flows.

It offers several key advantages:

- Maximized heat exchange surface, covering the entire tank, bottom, or walls as needed.

- High mechanical flexibility, as the pressure of the utility fluid does not add stress to the main tank.

- Total adaptability: ability to equip large-diameter tanks, thick bottoms, or design independent panels (radiant panels, cryogenic shields, etc.).

WHY CHOOSE ZIEMEX SINGLE EMBOSSED PILLOW PLATES?

At ZIEMEX, we have been experts in the design and manufacturing of single embossed pillow plates for over 30 years. Our solutions offer:

- superior thermal performance compared to half-pipe coils,

- design flexibility (shapes, sizes, special materials),

- proven mechanical safety even in extreme conditions (up to 20 barg and -200°C / +400°C),

- a sustainable and cost-effective solution thanks to reduced energy consumption and improved overall efficiency.

In short, while half coils continue to be a proven solution for simple applications, single embossed pillow plates offer a modern and efficient alternative that is ideally suited to the requirements of current industrial processes.

TWICE AS FAST COOLING

with indisputable thermal efficiency

An analysis of the cooling curve clearly shows the superiority of single embossed pillow plates over half coils.

In the same operating conditions, a reactor equipped with a single embossed pillow plate reaches 11.5°C in only 2 hours, whereas the internal temperature remains at 15°C with half coils. That 3.5°C difference is the result of more efficient heat transfer, allowing faster cooling and thus improved process control.

Concretely, it leads to shorter cycle times, optimised energy consumption and additional safety for temperature-sensitive processes. A performance resulting from the design of the pillow plates themselves, which promotes utility fluid convection and maximises the exchange surface, whereas half coils offer less-active areas.

STANDARDS, TESTS AND ENDURANCE:

ZIEMEX guarantee

- TUV approval for the design of Ziemex quilted double jackets subjected to steam

- Decades of experience enabling the design of steam inlet devices in heating circuits, specifically engineered to ensure both robust mechanical resistance and optimal steam distribution.

- Design validation through burst testing

- Fatigue test results where quilted double jackets laser-welded were subjected to alternating pressure cycles at a rate of 8 to 10 cycles per minute. The test was stopped at 12,000 cycles (without failure) due to the duration of the test.

- We can guarantee that laser-welded quilting will outperform welded half-pipe coils in cases of combined temperature and pressure cycling.

- Our space simulation cryogenic panels (cryogenic shields) also operate with cycles ranging from -200°C to +200°C in just a few minutes, without fatigue failure.

- For a leading European space industry company, we replaced conventional channel-based radiant panels—used to polymerize rocket booster propellant—with quilted double jacket systems.

Need a reactor for your chemicals, biotech or pharma plant?

ZIEMEX can adapt to your processes, reactions and cleaning and layout requirements. Our technical staff work along with your quality, production or validation teams to ensure fast and compliant commissioning.