Home > Processing equipment > Custom industrial reactors > Custom XXL coil type industrial reactors

Custom XXL coil type industrial reactors

Extreme capacities and requirements, proven know-how.

ZIEMEX has been designing and building very large reactors for over 60 years to meet the most demanding industrial requirements.

A coil type reactor is a reactor with half coils welded to the outer wall, within which a utility fluid circulates (water, steam, thermal oil).

This system heats or cools the product contained in the tank.

Robust and easy to implement, it offers a reliable solution, albeit with a smaller heat exchange surface than with single embossed pillow plates.

Our industrial fermenters can provide up to 150m³ of useful volume and measure 5 metres in diameter, and are made in a single piece.

That performance level makes it possible to meet the requirements of large-scale reaction processes in industries such as biotechnology, chemicals, green chemicals and ingredient manufacturing.

unique expertise

in the management of XXL projects

The making of a reactor calls for full control over all constraints:

- Mechanical sizing (pressure, agitation requirements, impact resistance),

- Heat transfer suited to specifications,

- Corrosion resistance with control over the use of all existing materials (stainless steel, duplex, nickel, titanium, zirconium, Hastelloy)

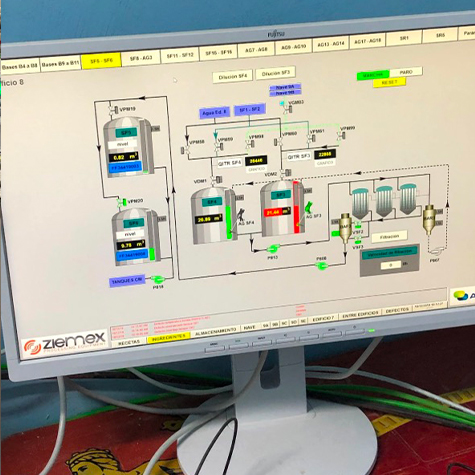

- Incorporation of all functional parts (internals, agitation and impellers, instrumentation, CIP/SIP, safety, utility skids, regulation loop, etc.),

- Strict compliance with standards PED 2014/68/EU, ATEX, GMP, ASME

For such projects, ZIEMEX mobilises its expert teams in engineering, metallurgy, processes, and its integrated manufacturing factory.

Custom projects

to boost your performance

Our designs are always directly based on the particularities of your processes. ZIEMEX agrees to deliver reliable and safe equipment that is ready for use, and incorporated into the other elements of your unit (skit, regulation loop, automation, etc.).

Reactors that are tested

and approved in the field

Our special inlet systems allow the introduction of hot fluid in our half coils and considerably reduce the risk of cracks over time in this sensitive part of the equipment.

These solutions have now been proven by over 30 years’ use in reactors across the world.

Get in touch to discuss your XXL projects

Do you have plans for a large-capacity project?

Talk to us about your dimensional, process and layout requirements.

Our engineers are on hand to support you from design to installation.