Home > Processing equipment > Custom industrial reactors > Revamping with custom clamp-on plate coils

Revamping with custom clamp-on plate coils

Transform your existing processing tanks and reactors

Thermal performance in a single piece of equipment.

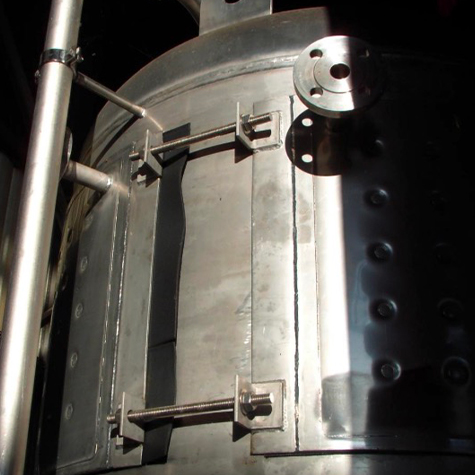

In existing equipment such as reactors or process tanks, an exchange surface can be added on the outside to improve thermal performance with no need for major revamping work.

This system enables existing equipment to be refitted at a reduced cost in order to ensure temperature maintenance, without replacing the entire existing device.

We insert a conductive cement between the clamp-on plate coils and the tank to improve heat transfer.

TEMPERATURE CONTROL

through added external surfaces

When you need to add thermal power, we install external heat exchange surfaces to the equipment.

This enables us to:

- guarantee uniform temperature maintenance,

- revamp existing equipment,

- limit uncovered areas.

ZIEMEX

Comprehensive support

From process design up to installation at your site, we provide support at every step of the way.

Our custom solutions are supplied with instrumentation, safety components and compliant technical documentation.

Does your process require robust material transfer and precise heat regulation?

At ZIEMEX, we provide customised solutions.