Home > Processing equipment > Custom industrial reactors

Custom industrial reactors

ZIEMEX know-how for your chemical and biological reactions.

Our custom-designed industrial reactors meet the highest requirements in terms of performance, cleanability and regulation of chemical processes.

Industrial reactors occupy a central place in a number of industrial processes, whether chemical synthesis, pharmaceuticals formulation, biotechnology or polymer making.

To guarantee optimum reactions and consistent reliability, the equipment must address particularly high requirements in respect of heat regulation, agitation, corrosion resistance, and safety, and enable complete control over reactions.

At ZIEMEX, we design and manufacture industrial reactors that are entirely custom-built, sized to suit your needs and layout requirements and the particularities of your reactions or processes.

We work both on standard equipment and on complex projects that require the seamless integration of peripheral devices (agitation systems, safety components, instrumentation, regulation, skids etc.).

OUR REACTORS ARE DESIGNED TO GUARANTEE:

- optimum homogenisation (CFD simulation possible),

- effective heat transfer (additional internal surfaces can be included if needed),

- full cleanability (up to < 0.6µm roughness with mechanical polishing and more with electropolishing),

- strict compliance with applicable requirements and standards.

A COMPLETE RANGE OF INDUSTRIAL REACTORS

for all applications

ZIEMEX offers several types of reactor, adapted to the constraints of chemicals and green chemicals, biotechnology, pharmaceuticals and the ingredients industry:

Half coil type reactor

ZIEMEX has mastered this long-standing and recognised solution for heating or cooling a reactor, in terms of both thermal sizing and implementation.

Capacities up to 150m³ and 5 metres in diameter, made in a single piece and transported by inland waterway as necessary. ZIEMEX controls all the logistics and mechanical engineering stages of these types of projects.

Single embossed pillow plate reactor

Special design to guarantee optimum thermal performance and high mechanical resistance to thermal shocks and cycles, including with XXL volumes.

If high thermal power needs to be added or removed, we incorporate immersed heat exchange surfaces. Agitation impellers can be either welded or removable, polished and assembled according to proven internal procedures, incorporating cleaning requirements (CIP/SIP).

Clamp-on plate coils

In existing equipment such as reactors or process tanks, an exchange surface can be added on the outside to improve thermal performance with no need for major revamping work.

SOLUTIONS

designed for your manufacturing requirements

Each reactor is designed on the basis of a modular approach and is supplied with full technical assistance.

Our teams will help you select the configuration best suited to your process, and addresses all the requirements of your line of industry: ATEX, sterile zone, pressure, temperature, automated cleaning, connected instrumentation, etc.

CUSTOMER CASE

ZIEMEX has been supporting major players in the global chemicals industry for several decades now by supplying reactors of different types.

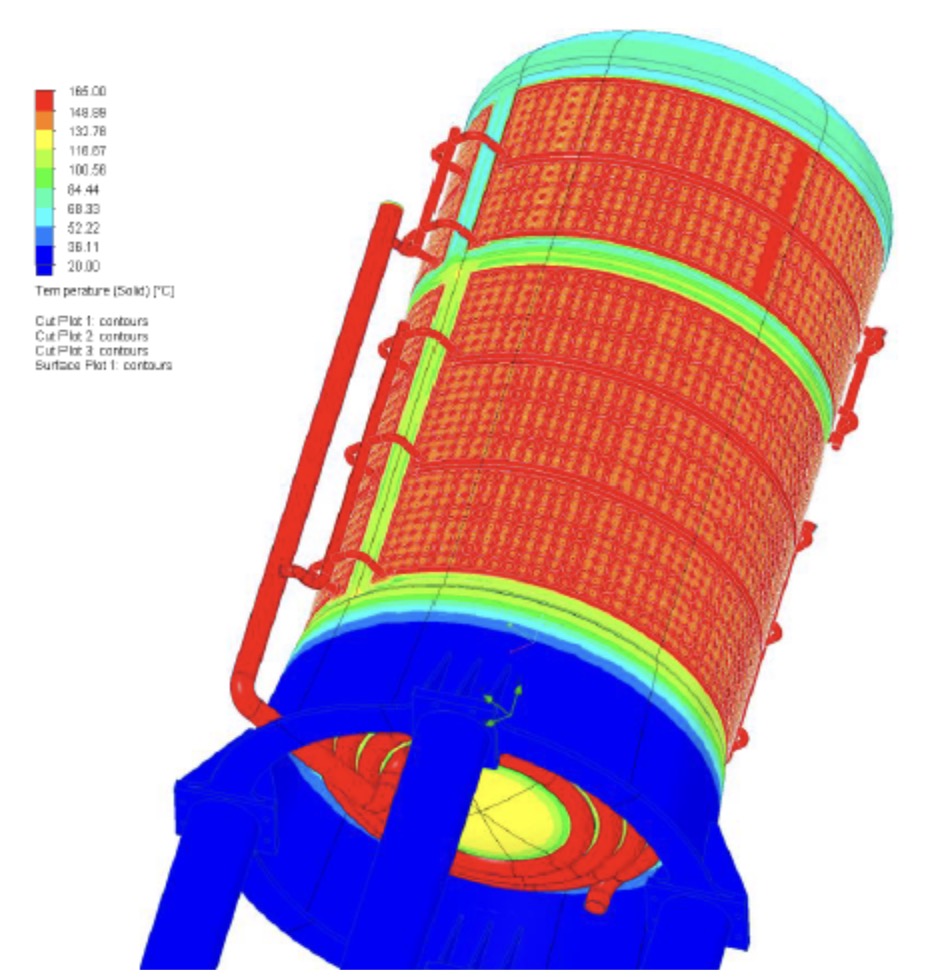

For a major European chemical company facing breakage problems in its exchange surfaces subjected to repeated thermal cycles, ZIEMEX proposed a special innovative design combining different technologies that have been proven by ZIEMEX over a long period.

The project gave rise to a CFD study to mechanically size the reactor subjected to combined pressure and temperature cycles.

The proposed solution was a hybrid one, with half coils and single embossed pillow plates.

Our experience of steam exchanges enables us to offer steam entry devices for heating circuits with a specially researched design which allows high mechanical resistance and also optimum distribution of steam.

Do you have a project

for an industrial reactor?

ZIEMEX can support you from the very early stages of your plans up to commissioning of compliant, sustainable and efficient equipment.