Home > Processing equipment > Custom industrial heat exchangers > Radiaplaques®

Radiaplaques®

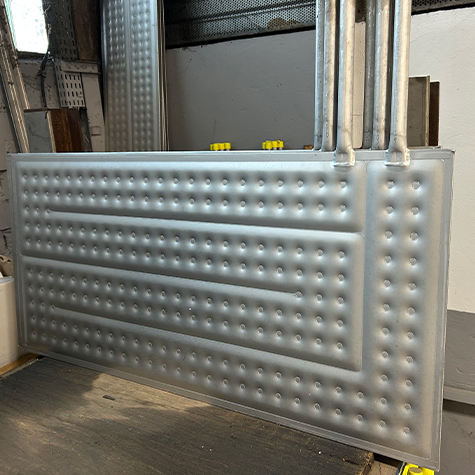

ZIEMEX Radiaplaques® are thermal exchangers designed to heat or cool baths, particularly in the surface treatment sector.

They operate on the same principle as pillow plates, but with Radiaplaques®, there are standard models available which can be quickly and simply adapted to suit the customers’ surface treatment tanks (galvanisation, silver plating, degreasing, phosphation, anodising, chromating, electrolytic nickel-plating, copper-plating, etc.).

This equipment provides a reliable, safe alternative to electrical resistance, reducing the associated risks while ensuring high-performance, uniform heat transfer.

OUR RADIAPLAQUES®

solutions

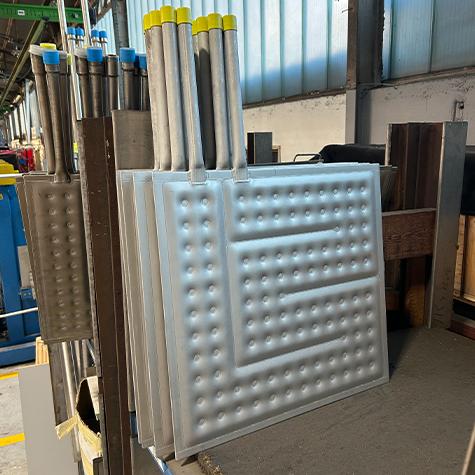

We offer four ranges of standard Radiaplaques®:

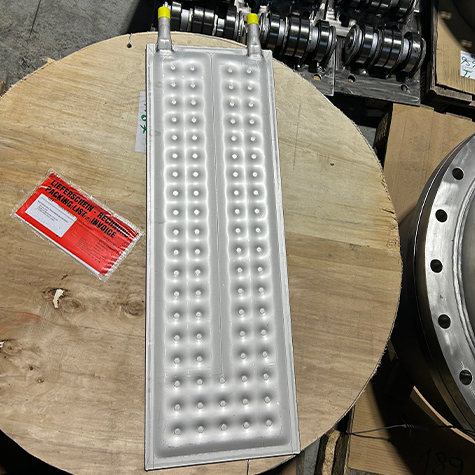

Series 6S and 12S: fixed width of 300 mm or 560 mm respectively, with variable height (600 to 1200 mm, depending on the model).

Series 6T and 12T: fixed height of 300 mm or 560 mm respectively, with variable width (600 to 1200 mm, depending on the model).

These different dimensions enable the type of Radiaplaques® to be suitably adapted to meet the needs of each treatment basin. As an option, the plates may be equipped with two handles, making them easier to move.

Our standard models cover the majority of applications, however, we also offer custom versions in all available materials (stainless steel, titanium, Hastelloy®, zirconium, duplex, superduplex, etc.)

TECHNICAL SPECIFICATIONS

to boost your performance

Our standard Radiaplaques® are manufactured in stainless steel 316L, with some sizes available in titanium (6T3 and 12T3).

The metal sheets used are 1.5 mm thick, and welded together with laser welded circular beads. After welding, the plates are inflated in order to deform the sheet metal and create channels enabling the hot or cold utility fluid to circulate.

This design guarantees excellent thermal exchange, as the surface is optimised to maximise contact between the plate and the bath while maintaining a great degree of mechanical flexibility.

The operating pressure is 15 bar and testing pressure can reach 21.5 bar, ensuring a high level of safety.

The connections use standard 26.9 x 2.6 threaded conical gas tubing, but this may be adapted depending on the customer’s specific needs.

EXAMPLE

of use

For a customer in the surface treatment sector, we provided several Radiaplaques® designed to quickly heat chemical treatment baths.

Standard series 12S models were selected, as their width was suitable for the dimensions of the basin and they were easy to install.

Due to their compact design and laser welded technology, these Radiaplaques® enabled the electrical resistances to be replaced effectively. This reduced the safety risks while also improving thermal performance.

Do you have a project?

Talk to us about your dimensional, process and layout requirements.

Our engineers are on hand to support you from design to installation.