Home > Processing equipment > Custom industrial heat exchangers > Pillow plates

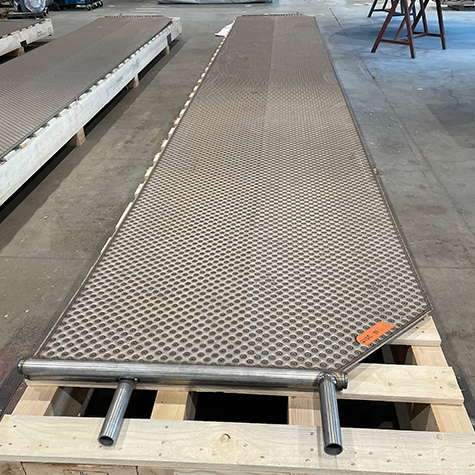

Pillow plates

to guarantee thermal performance

ZIEMEX pillow plates are an essential part of a complete thermal system.

Each plate consists of a single circuit which fluid circulates around. Its design meets the specific requirements of the customer’s process. Even though final assembly of the equipment as a whole is often carried out by another supplier, the design and manufacture of the plates requires specialised expertise in order to guarantee thermal performance, mechanical resistance and long-term reliability.

At ZIEMEX, we have acquired comprehensive expertise in laser welding since 1995, and currently have three such machines. This extensive experience means that, as a supplier, we can weld plates in any material: stainless steel, duplex, superduplex, titanium, Hastelloy, zirconium, etc.

All our welding is carried out in line with the customer’s requirements: calculation codes, design temperatures and pressures, pressure drops to be adhered to and specific thicknesses.

Pillow plate

solutions

ZIEMEX pillow plates are designed to be customised to suit all types of process and requirements.

Our teams carry out testing on a test bench in order to validate the weld pitch and confirm pressure drops. This means that we can ensure that each plate meets the customer’s hydraulic and mechanical requirements.

We also carry out burst testing in order to obtain welding certificates, combining internal testing and fast partnerships to guarantee that certificates are available soon after ordering. This approach ensures that the solution is customised and suitable for the specific requirements of the process, and that it is robust, safe and reliable.

In addition to the standard plates, we also produce special pillow plates that are fitted and directly integrated within the reactors or fermenters in order to improve the thermal efficiency of these devices. For these challenging applications, the metal sheets can be up to 3 or 4 mm thick, guaranteeing durable mechanical resistance in line with the pressure and temperature requirements.

We are also able to assemble several plates to create genuine thermal batteries, suitable for strong exchange forces and significant volumes.

Finally, at ZIEMEX, we design and manufacture heat shields (thermal shrouds) made of 1.5 to 2 mm sheet metal, which are welded and then fitted. These shields are used in thermal vacuum chambers to enable companies to simulate the conditions of space and test, for example, the thermal resistance of their satellites.

Technical specifications

to boost your performance

We design pillow plates in the material best suited to your process, whether that be standard stainless steel such as 304L, 316L or 321L, high alloy stainless steel such as duplex or superduplex, titanium, Hastelloy®, zirconium or other specific alloys, in line with the requirements of your application.

The design is validated through testing on a test bench, which enables pressure losses to be controlled and optimised. Design pressures and temperatures are adapted to meet the needs of each customer, with weld pitch and burst testing verification in order to guarantee the reliability of our equipment. Our pillow plates are sized to operate in an absolute vacuum (-1 barg) and can withstand service pressures of up to 60 barg, with hydraulic tests carried out up to 100 barg.

They can also be optimised in terms of their thickness, to reduce the weight of the assembly while maintaining excellent thermal, hydraulic and mechanical performance.

Example

of use

For a customer’s chemical process for crystallisation, at ZIEMEX, we manufactured pillow plates in 321L. They were selected to withstand a high temperature, by design, while also remaining economical.

The thickness of the material was optimised to reduce the weight of the equipment, and the design of the plates enabled pressure drops to be minimised, increasing the number of operational cycles.

In-house testing validated the weld pitch and confirmed mechanical reliability. Thanks to ZIEMEX’s extensive experience in laser welding and our ability to adapt the material, thickness and weld pitch, we were able to provide a fully customised, robust solution which met the customer’s specific requirements.

Do you have a project?

Talk to us about your dimensional, process and layout requirements.

Our engineers are on hand to support you from design to installation.