Home > Processing equipment > Custom industrial fermenters > Sterile industrial fermenters

Sterile industrial fermenters

Designed to meet the highest hygiene and safety standards.

ZIEMEX has been designing and building very large fermenters for over 60 years to meet the most demanding industrial requirements.

Fermentation processes in pharmaceuticals and biotech environments call for absolutely sterile conditions. ZIEMEX fermenters are designed to allow strict control over contamination, cleaning and regulation.

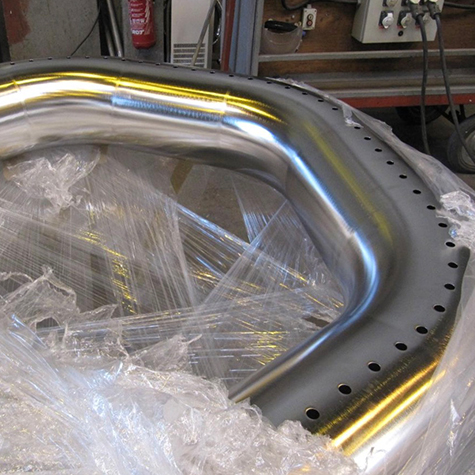

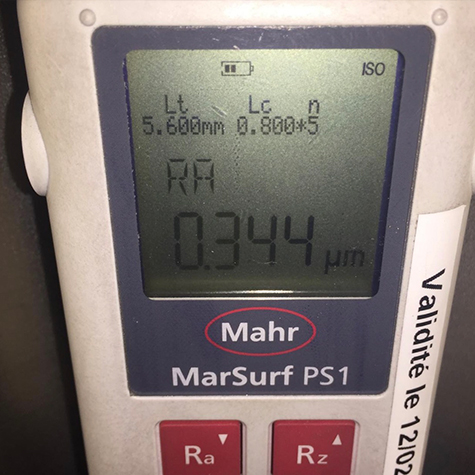

Each piece of equipment is conceived as a closed, aseptic and perfectly controlled environment: internal roughness < 0.6µm, polished welds, sterile connections and integrated CIP/SIP systems for cleaning and sterilisation in place with no manual intervention.

Critical subassemblies – spargers, agitation impellers, instrumentation – are mounted according to validated in-house protocols for complete traceability and total reproducibility of the process.

These fermenters are designed for optimised integration in pharmaceuticals or biotechnology production lines, and guarantee a continuous sterile environment encompassing preparation, fermentation and product recovery.

COMPLETE CONTROL

over sterility

ZIEMEX uses proven manufacturing procedures to guarantee optimum finishing:

- Final internal roughness < 0.6µm, even for large volumes,

- Polishing and welding of agitators in the workshop, following a specific assembly procedure,

- Subassembly in a controlled environment,

- Systematic quality control (visual, dimensional, metallurgical, Ra, etc.).

These standards are applied to fermenters, including XXL models, to guarantee consistent performance regardless of volume.

FOR ALL YOUR ENVIRONMENTS,

however critical

Our equipment meets the most stringent safety and environmental standards:

- GMP, ATEX, PED 2014/68/EU compliance,

- Can be integrated into sterile zones or clean rooms,

- Complete traceability and technical documentation supplied with the equipment.

COMPONENTS

designed to allow cleaning

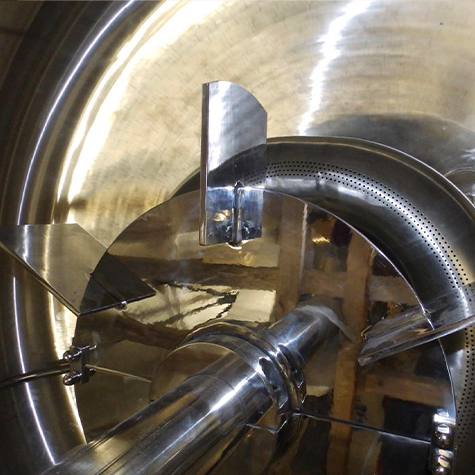

The spargers incorporated into the tanks are designed to optimise gas transfer while allowing reliable cleaning in place (CIP) and sterilisation (SIP).

Each detail (shape, holes, connections) is designed to limit retention areas and allow continuous sterility between cycles..

Do you need a sterile fermenter for your biotech, pharma or R&D facility?

ZIEMEX can adapt to your processes, ferments and cleaning and layout requirements. Our technical staff work along with your quality, production or validation teams to ensure fast and compliant commissioning.