Home > Processing equipment > Custom industrial fermenters

Custom industrial fermenters

To optimise your biotechnology and industrial processes

Our custom-designed industrial fermenters meet the highest requirements in terms of performance, sterility and regulation of biological processes.

Fermentation is a key stage in the exploitation of biomass and products derived from bioconversion. To guarantee optimum efficiency and consistent reliability, the equipment must meet strict technical requirements: sterility, Clean-in-Place (CIP), heat regulation, homogenisation, material transfer, and regulatory compliance (PED 2014/68/EU, GMP, ATEX).

Drawing on over 60 years of expertise in designing process equipment, ZIEMEX designs and manufactures industrial fermenters that are entirely custom-built, sized to suit your needs and layout requirements and the particularities of your ferment or processes.

We work both on standard equipment and on complex projects that require the complete integration of peripheral devices (spargers, safety components, instrumentation, regulation, skids etc.).

OUR FERMENTERS ARE DESIGNED TO GUARANTEE:

- perfect sterility (up to < 0.6µm roughness),

- optimum homogenisation (CFD simulation possible),

- effective heat transfer (additional internal surfaces can be included if needed),

- strict compliance with the requirements of regulated industries.

A COMPLETE RANGE OF INDUSTRIAL FERMENTERS

for all applications

ZIEMEX offers several types of fermenter, adapted to the constraints of biotechnology, pharmaceuticals, green chemicals, cosmetics and the ingredients industry:

LIEN FR: biotechnologie, de la pharmacie, de la chimie verte, des cosmétiques ou de l’industrie des ingrédients :

XXL industrial fermenters

Capacities up to 600m³ and 6 metres in diameter, made in a single piece and transported by inland waterway.

ZIEMEX controls all the logistics and mechanical engineering stages of these types of projects.

Sterile fermenters

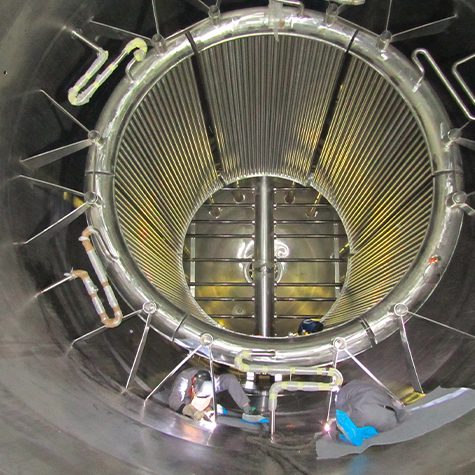

Special design to guarantee high levels of sterility, including in XXL volumes. Agitation impellers are welded, polished and assembled according to proven internal procedures, incorporating cleaning requirements (CIP/SIP).

Our spargers are also designed to ensure sterility.

Agitated fermenters with internal exchange surfaces

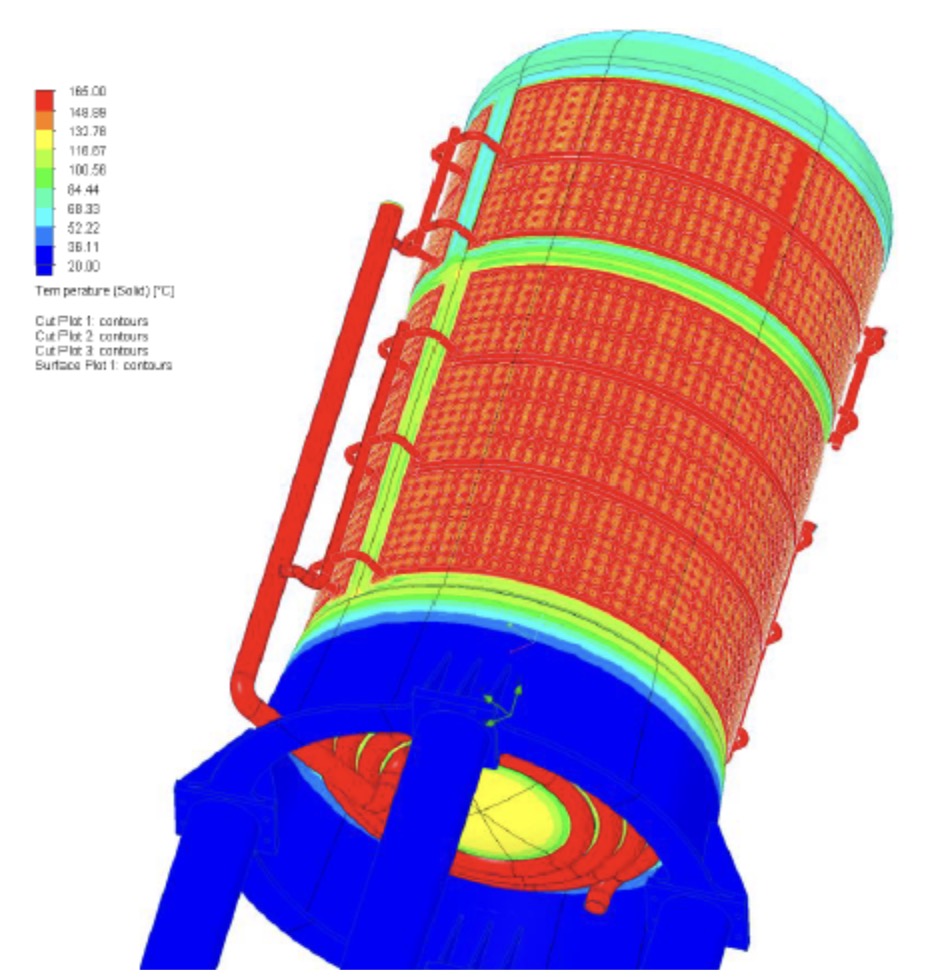

Agitation is a key parameter: it is used for homogenisation and effective material transfer (kLa). In addition to analytic sizing, we also run CFD simulations to validate the parameters on a pilot or industrial scale.

If large quantities of power are to be dissipated, we integrate immersed heat exchange surfaces that limit contamination risks.

Bubble column fermenters

For certain types of ferment and process, mechanical agitation is not required.

We offer bubble column fermenters optimised for optimal transfer of material using spargers adapted to each need.

SOLUTIONS

designed for your manufacturing requirements

Each fermenter is designed on the basis of a modular approach and is supplied with full technical assistance.

Our teams will help you select the configuration best suited to your process, and addresses all the requirements of your line of industry: ATEX, sterile zone, pressure, temperature, automated cleaning, connected instrumentation, etc.

CUSTOMER CASE

As a legacy supplier of fermenters for breweries, ZIEMEX made its mark in 2006 as a partner for the biotech industry by supplying sterile equipment to pilot platforms and then industrial facilities for the ingredients, cosmetics, biofuel, pharmaceuticals and yeast industries.

Thanks to our experience and expertise in single embossed pillow plate technology, heat transfers are optimised and controlled for efficient sterilisation, CIP and fermentation cycles.

The associated hot and cold thermal cycles are handled by the plates, which have a high fatigue resistance over time.

In addition, CFD studies can be offered to mechanically size fermenters subjected to combined pressure and temperature cycles.

Our experience of steam exchanges enables us to offer steam entry devices for heating circuits with a specially researched design which allows high mechanical resistance and also optimum distribution of steam.

Do you have a project for an industrial fermenter?

ZIEMEX can support you from the very early stages of design up to commissioning of compliant, sustainable and efficient equipment.