Home > Processing equipment > Custom industrial fermenters > Bubble column fermenters

Bubble column fermenters

For gentle fermentation with no mechanical agitation.

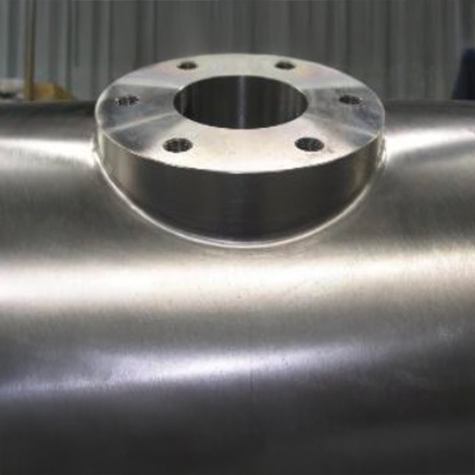

An effective solution without mechanical agitation. For some types of fermentation, particularly with sensitive ferments or in specific conditions, mechanical agitation can be replaced by the controlled diffusion of gas in a column.

ZIEMEX designs bubble column type fermenters that are perfectly adapted to these gentle processes.

Bubbles injected at the bottom of tank rise and create a homogeneous mixture, with gradual oxygenation and no mechanical stress. This configuration limits the risk of shearing, while ensuring efficient material transfer.

ZIEMEX columns are custom designed and sized based on the height to diameter ratio, the geometry of spargers and the cleaning and sterility requirements specific to biotech and pharmaceuticals.

Optimised

MATERIAL TRANSFER

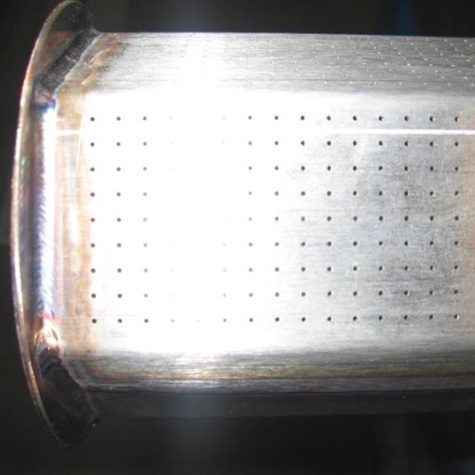

In a bubble column, mixing is achieved by injecting gas through spargers placed at the bottom of the tank. The rising bubbles achieve gentle mixing and gradual oxygenation, with limited shearing.

ZIEMEX designs custom spargers according to the parameters below:

- Gas/fluid flow rate

- Uniform bubble distribution,

- Orifice size and shape,

- Cleanability and sterility integrated from the design stage.

ZIEMEX

comprehensive support

From process design up to installation at your site, we provide support at every step of the way. Our custom solutions are supplied with instrumentation, safety components and compliant technical documentation.

PROVEN SOLUTIONS

for industry

Our bubble columns are used in a number of industrial processes:

- Production of food ingredients by starch and ingredient manufacturers,

- Bioconversion, culture of sensitive bacteria or yeast,

- Anaerobic or low-turbulence fermentation.

Each bubble column fermenter is designed with a specific L/D ratio, with a height suited to the required efficiency and incorporated into your other process equipment.

These fermenters do not use mechanical agitation:

- reduce maintenance costs,

- prevent contamination related to dynamic seals,

- ensure long-term robustness.

Are you looking for a gentle solution for your special fermentation needs?

Talk to ZIEMEX about our custom bubble columns.