Home > Processing equipment > Custom industrial fermenters > Agitated fermenters with internal exchange surfaces

Agitated fermenters with internal exchange surfaces

High performance mixing and temperature control in a single vessel.

Agitation plays a key role in fermentation processes. It helps homogenise the ingredients, promotes material transfer (kLa) and guarantees process stability. ZIEMEX designs custom agitated fermenters to meet these requirements.

Agitation impellers are selected and positioned depending on the type of culture, the viscosity of the medium and sensitivity of the ferment. The shaft and packing assembly is made to in-house procedures that guarantee sterile assembly and mechanical reliability over time.

When the thermal power to dissipate is large, ZIEMEX uses internal exchange surfaces (immersed bundles or coils) for even cooling without compromising cleanability or sterility. These surfaces are designed and polished to eliminate all risks of retention and optimise heat exchange.

Agitation systems

tailored to your process

Our fermenters include impellers designed to meet your requirements:

- Mixing of liquid, gas-liquid or liquid-solid phases

- Rotation speeds and profiles adapted to the sensitivity of ferment,

- High or low viscosity agitation capacity.

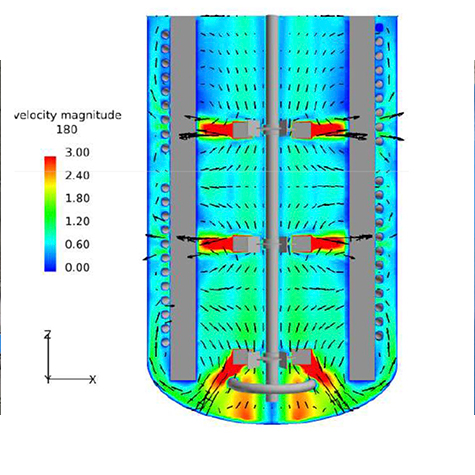

We perform analytical sizing complemented by CFD simulation to model the actual behaviour of the fluid on the industrial scale (scale-up from the pilot).

ZIEMEX

comprehensive support

From process design up to installation at your site, we provide support at every step of the way. Our custom solutions are supplied with instrumentation, safety components and compliant technical documentation.

Temperature control

via immersed internal surfaces

When the thermal power to dissipate is too large for single embossed pillow plates alone, we incorporate immersed heat exchange surfaces inside the tank (coil exchangers, internal bundles).

This makes it possible to:

- guarantee even cooling,

- avoid localised overheating,

- limit dead zones,

- protect sterility.

Do you need a sterile fermenter for your biotech, pharma or R&D facility?

ZIEMEX can adapt to your processes, ferments and cleaning and layout requirements. Our technical staff work along with your quality, production or validation teams to ensure fast and compliant commissioning.