Home > Processing equipment for sugar manufacturing and distilleries

Processing equipment for sugar manufacturing and distilleries

High performance, reliability and energy efficiency for sugar and spirits manufacturing processes.

ZIEMEX has been designing, manufacturing and installing thermal and chemical engineering equipment for sugar manufacturing and distilleries for over 60 years.

At a time when companies are looking to decarbonise and optimise their energy consumption, we help sugar manufacturers and distilleries improve their evaporation, concentration and processing processes.

Our expertise relies on control over heat transfer, mechanical sizing and the specific requirements for processing sugar juice and must.

We offer innovative solutions to reduce energy consumption, improve finished product quality and guarantee the sustainability of installations.

Continual adaptation

to market requirements and developments

Sugar manufacturers and distilleries are faced with major challenges:

- Reduction of energy consumption as part of decarbonisation.

- Optimisation of evaporation units by lowering the LMTD (logarithmic mean temperature difference) while maintaining high exchange coefficients.

- Efficient control of volumes of juice and must to limit residence time and keep the products from changing colour or being degraded.

- Capacity to condense maximum steam, including in the presence of inert gas.

- Controlled manufacturing costs in spite of heightened thermal and mechanical requirements

ZIEMEX provides an answer to these challenges with dedicated R&D programmes and design innovations that improve the overall performance of plant while meeting the cost and environmental requirements of the sugar manufacturing and distillery industries.

ZIEMEX solutions

for sugar manufacturing and distilleries

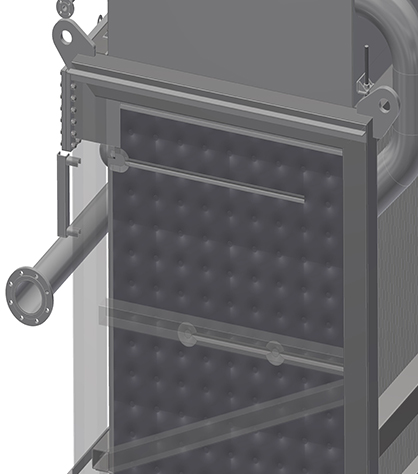

ZIEMEX develops evaporators and welded plate heat exchangers specifically adapted to the needs of these markets.

Efficient

evaporation

Our equipment operates over a wide range of pressure values (-1 to several bars) and sugar contents (15 to 75%). When the LMTD is above 1.2°C, the exchange coefficient remains constant: below that, it decreases slightly but remains efficient, allowing multiple-effect use. Our solutions are designed to be incorporated in multiple-effect processes and combined with mechanical vapour recompression (MVR) systems.

Easier maintenance and cleaning

Plate spacing can be adapted to limit the risk of fouling and make cleaning simpler. That flexibility guarantees sustainable operation and optimised maintenance, even for the most demanding processes.

Management

of inerts

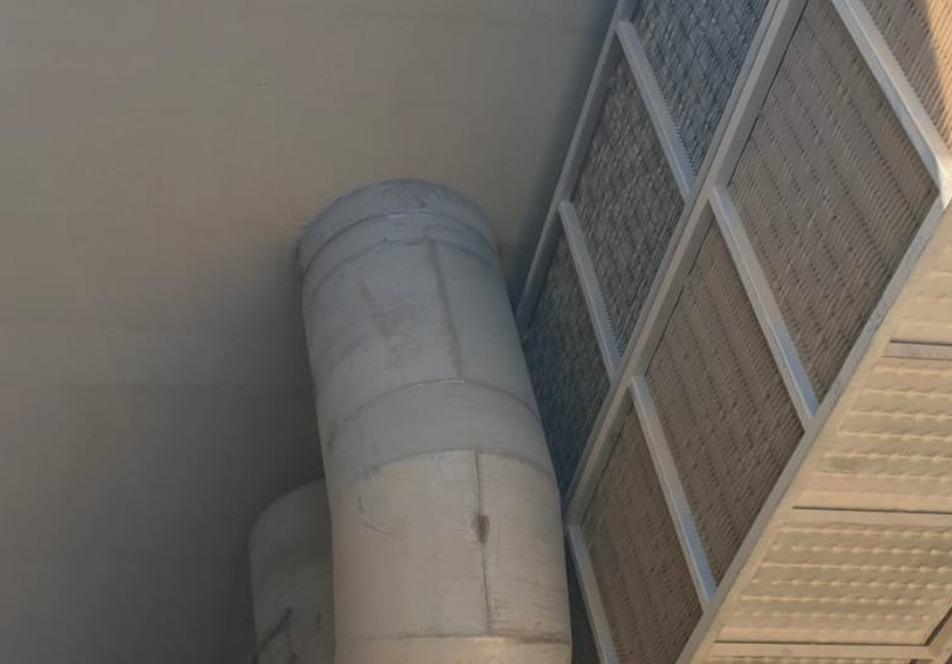

With a patented final baffle system, the gas is accelerated and dead zones are removed for optimum condensation.

Homogeneity

of exchange

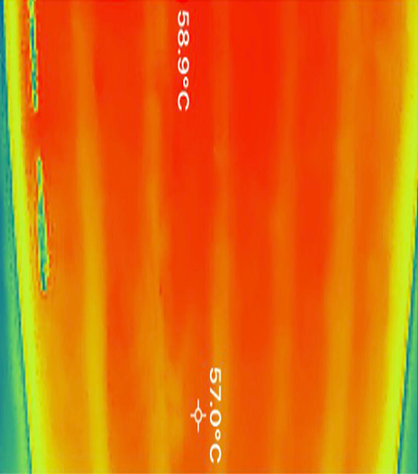

Infrared thermography tests have demonstrated that heat is distributed evenly, with differences below 0.1°C in stabilised operation.

Reduction

of residence time

Our evaporators limit the passing time of the juice or must to less than 5 minutes per equipment, thus minimising colour changes and other alterations using baffles and optimised distribution containers.

Flexibility

and integration

Our bundles are modular in design, making it possible to obtain up to 12,000m2 in a single block. They are perfectly suited for revamping installations to increase your production capacities and/or reduce your energy costs.

These features result in:

- significant reduction of energy consumption,,

- improved product quality (sugar, alcohol, bio-ethanol), and

- simplified maintenance.

References &

accomplishments

ZIEMEX has supported several major sugar manufacturers and distilleries in France and internationally.

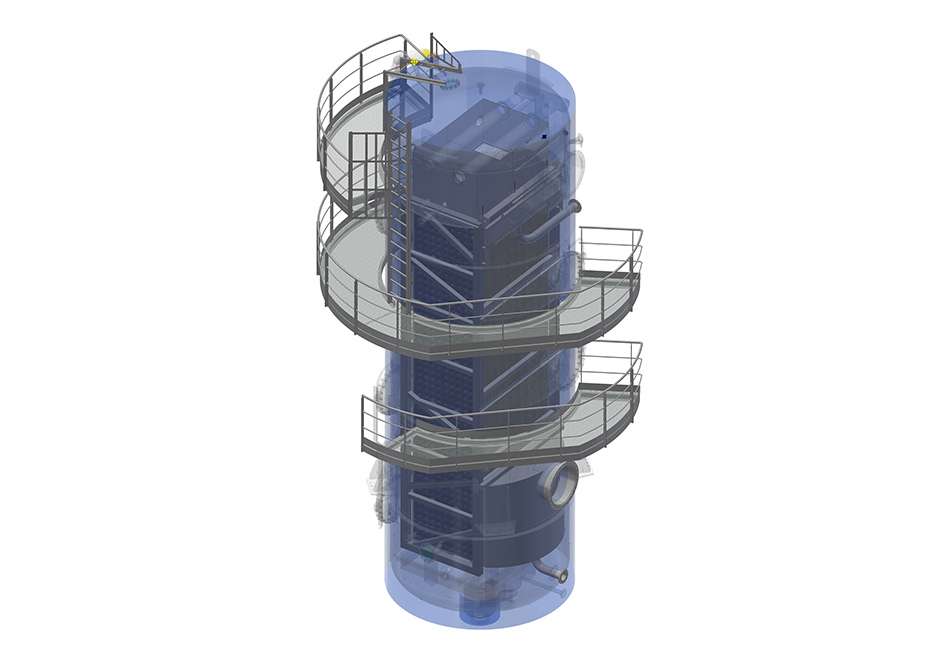

One salient project required the design and installation of a complete evaporation and concentration station using mechanical vapour recompression for the Canal Sugar plant:

- Evaporation capacity: 1,298 t/hours of juice.

- Configuration: 5 effects combined with mechanical vapour recompression to achieve a final Brix value of 76%.

- Results: over 110,000m2 of exchange surface, for remarkable energy efficiency.

Our latest project was for a large French sugar factory for which we designed and installed a complete evaporation unit:

- Evaporation capacity :

- 200 t/hours of juice.

- Configuration: 3 effects combined with mechanical vapour recompression.

- Results:

- significant improvement of energy efficience with unparalleled performance,

- total decarbonising of pre-evaporation.

- reduction of live steam consumption and optimisation of operating costs.

These project examples confirm ZIEMEX’s ability to offer robust and efficient solutions tailored to the developments in these markets.

Do you have a project?

ZIEMEX supports sugar manufacturers and distilleries with their energy transition and in optimising their processes with the help of innovative and efficient equipment. Get in touch today to discuss your project!