Home > Processing equipment for pharmaceuticals and biotechnology

Processing equipment for pharmaceuticals and biotechnology

Absolute purity to guarantee high performance, traceability and health safety.

With over 50 years’ experience in bio-industry, ZIEMEX has the know-how to design, manufacture and install custom process equipment for the pharma and biotechnology industries.

As a recognised partner of major healthcare companies, we help our customers meet their need to control temperature and sterility and regulate biological processes.

Encompassing XXL industrial fermenters, sterilisation skids, concentration skids and Thermipack® equipment, our solutions combine high performance, traceability and compliance with the requirements of sterile environments.

ZIEMEX is a key player in the development and production of biologics, vaccines, enzymes, cell cultures and products requiring fermentation.

Challenges and requirements

of the pharmaceuticals and biotechnology market

The pharmaceuticals and biotechnology industries require installations that are impeccably clean, with absolute temperature stability. Their sensitive processes call for integrated design to guarantee safety, repeatability and efficiency.

Key challenges:

- Ensuring that process lines and equipment are fully sterile (CIP/SIP).

- Ensuring accurate temperature regulation (±1°C) for fermentation, formulation or purification processes.

- Integrating compact and modular solutions (process skids) that meet GMP standards.

- aking cleaning, maintenance and validation easier.

- Reducing energy consumption and optimising utilities (purified water, vapour, thermal fluid).

- Ensuring traceability and document compliance (materials, welding, testing, FAT/SAT).

ZIEMEX meets those requirements through complete process engineering combining mechanical design, heat transfer sizing and the integration of auxiliary equipment (valves, instrumentation, automation systems).

ZIEMEX solutions

for pharmaceuticals and biotechnology

ZIEMEX designs and manufactures equipment and environment on a turnkey basis, including vessels, heat exchange and automation systems. Our solutions are adapted to the needs of production and development, from pilot laboratories to manufacturing units.

Process skids

- Fermentation skids: accurate control of biological reactions, control of temperature, pH, dissolved oxygen, agitation.

- Sterilisation skids: heat treating of media, purified water loops, product circuits.

- Concentration/distillation skids: gentle separation under a vacuum with controlled heat loss.

- Preparation and cleaning skids (CIP/SIP): automated, compliant with pharmaceuticals standards.

Tanks and fermenters

- XXL sterile industrial fermenters for microbial or enzyme cultures.

- Bioreactors and tanks for inoculum with controlled agitation.

- Sterile process tanks for formulation, storage and homogenisation.

- Feed batch and buffer tanks with single embossed pillow plate.

Integrated thermal technology

- Welded plate heat exchangers for accurate regulation of fermentation, concentration and sterilisation temperatures.

- Vacuum condensers: for concentrating solutions or recovering solvents.

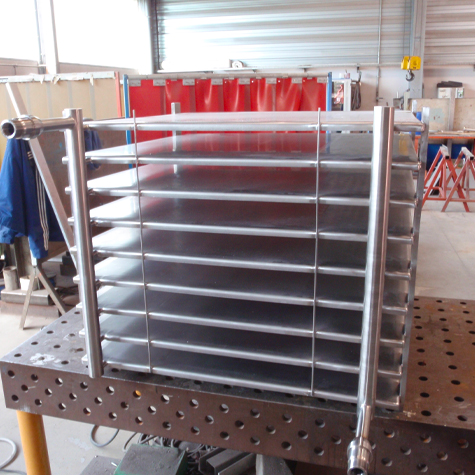

- Integrated single embossed pillow plate for heating and cooling, to ensure perfect temperature homogeneity.

- Drying trays: for even and gentle drying of sensitive products.

Each ZIEMEX solution is designed, manufactured and tested in our factory with possible FAT (Factory Acceptance Test) in actual conditions before on-site installation.

Customer cases

ZIEMEX has supported a number of customers in the refinery, biotech and pharmaceuticals industries.

ZIEMEX provides assistance to many pharma and biotechnology companies in France and elsewhere. Our projects have demonstrated our ability to design sterile, efficient and traceable equipment that meets the most demanding GMP, FDA and PED standards.

Sterile 100m³ fermenter for industrial microbial culture

Working for a pharmaceuticals manufacturer, ZIEMEX designed and made a sterile 100m³ fermenter for large-scale microbial culture processes.

- Materials and finishing: Polished 316L standard steel with Ra < 0.6µm internal roughness for optimum aseptic conditions.

- Dimensions: Ø 3,800 mm and useful height 10,000 mm.

- Temperature regulation: 86m² single embossed pillow plate with a 93m² internal coil to dissipate exothermic power of 2,900 kW and maintain the temperature at 37°C.

- Agitation and homogeneity: complete integration of agitation system in the factory, with counter blades and insulation, for even temperature distribution and close process control.

This project illustrates ZIEMEX’s expertise in large-capacity sterile volumes and the seamless integration of thermal, mechanical and biological functions in the same piece of equipment.

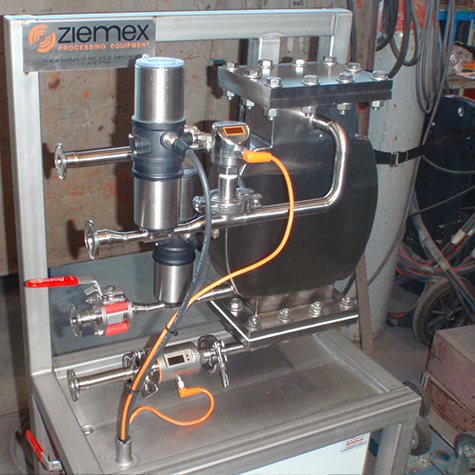

Cooling and grinding skid for Ceftiocyl production

As part of a pharmaceuticals manufacturing process, ZIEMEX developed a cooling and grinding skid for manufacturing Ceftiocyl.

- Application: maintenance of product temperature after grinding to preserve its properties.

- Thermal performance : cooling of the fluid by approximately 4.5°C, to keep the average temperature stable at 37°C throughout the process.

- Instrumentation and regulation: temperature sensors placed at each stage and automatic valves for precise regulation of water and product.

- Hygienic construction: heat exchangers and piping in stainless steel 316L, design meeting GMP requirements, with automated SIP cleaning.

- Process optimisation: design validated after testing to guarantee thermal stability, regulation system robustness and flow control during transfer and grinding.

This compact automated skid reflects the capability of ZIEMEX to integrate thermal performance, precise regulation and the hygiene compliance required in pharmaceuticals environments, all in a single model.

Do you have a project?

ZIEMEX puts its expertise in stainless steel boilerwork and thermal processes at the service of the biotech industry. Our fermenters, bioreactors, sterilisation skids and heat exchangers make pharmaceutical and biotechnology processes more reliable and efficient. Discover our process skid and sterile equipment solutions or get in touch to discuss your project.