Home > Processing equipment for petrochemicals

Processing equipment for petrochemicals

reliable and efficient solutions for industry

Control over heat flows is a key requirement in refining and petrochemicals units. Processes consume large quantities of energy (steam cracking, catalytic reforming, steam methane reforming, cryogenic distillation, etc.), and thermal integration can help significantly reduce fuel and steam consumption.

ZIEMEX has been designing and manufacturing custom heat exchangers for over 60 years to ensure that they can withstand extreme pressures and temperatures, corrosive fluids and severe feedstock variations.

Our expertise in heat transfer sizing (HTRI) and heavy boilerwork enables us to design solutions that offer operators reliability and efficiency.

challenges and requirements

of the petrochemicals market

Refining and petrochemicals impose some of the most demanding service conditions in industry:

- Very high temperatures (up to 850°C at the exit of the pyrolysis furnace) and high pressures (> 50 bars)

- Corrosive fluids and complex feedstock that requires the use of high-quality materials (titanium, Hastelloy®, Inconel®, duplex, etc.).

- Rapid fouling (quench exchangers, hydrocarbon effluent): need for robust and easy-to-clean design.

- Need for energy integration to reduce gas and steam consumption.

- Strict compliance with international standards (PED, CODAP, ASME, API, ATEX).

ZIEMEX satisfies these requirements with its proprietary heat exchanger technology: Ziepack®, Z-compact®, Zieplate®, Z-tubex® Ziebloc®, which combine safety, high performance and sustainability.

ZIEMEX solutions

for petrochemicals

Shell & tube heat exchangers

Typical applications:

- Rapid cooling of cracking gases (quench exchangers).

- Heating/preheating of feedstock in catalytic reforming units.

- Heat exchange in steam methane reforming (SMR) units.

- Condensers and reboilers for distillation columns.

- Feedstock/effluent economiser

The advantages :

- Mechanical robustness: suitable for high pressures and temperatures.

- Cleaning and maintenance made easier (removable bundles).

- Durée de vie élevée en conditions sévères.

- Flexible design: multi pass, floating bundle, double tube for high pressures.

- Sizing optimised using HTRI: maximum precision and reliability.

Welded plate heat exchangers

Typical applications:

- Compact integration of several bundles in a shell for cryogenic separation (ethylene/propylene, gas treatment).

- Heat exchanger reactor for precise control (temperature and metering of reagents) of continuous reactions (catalytic system, polymerisation)

- Feed-effluent reactor, Combined heat exchanger

- Economisers

- High-efficiency heat recovery in utilities systems.

- Thermal integration between clean fluids (feed ↔ effluent).

- Closed cooling loops (oil, thermal fluid, demineralised water).

- Vacuum condenser to improve distillation capacities

- Evaporator

Benefits

- Compact: high exchange surface in a small space.

- Low head loss: suitable for continuous processes and very low pressures with no loss of efficiency.

- Welded technology (seamless): suitable for high pressures and hazardous fluids.

- Unit exchange surface up to 16,000m²

Customer cases

ZIEMEX has supported a number of customers in the refinery and petrochemicals industry with large-scale projects

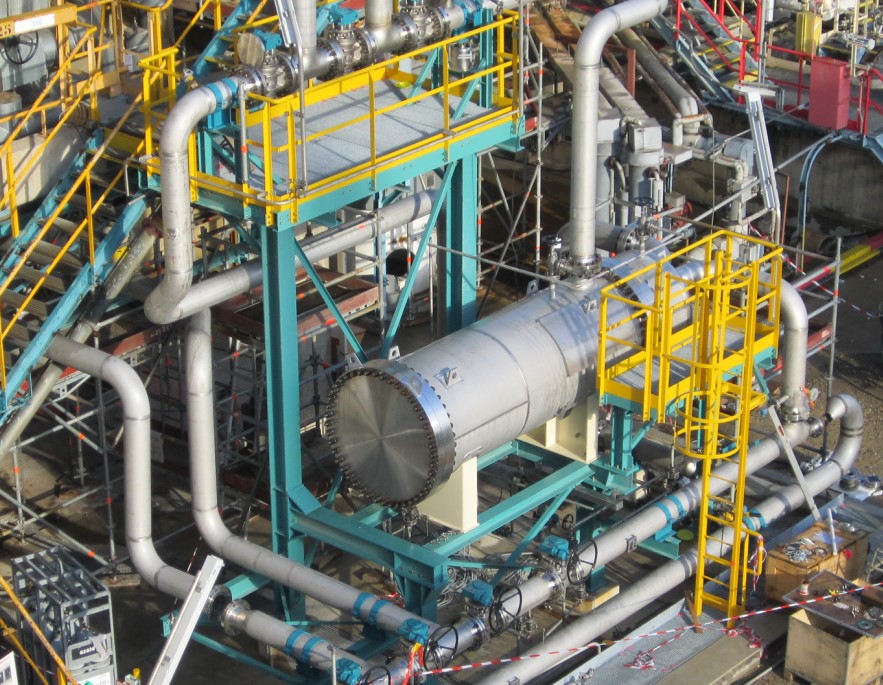

Steam cracking – Shell & tube quench exchanger

- Rapid cooling of pyrolysis gas at 850°C

- High-temperature shell & tube heat exchanger of the BEM type according to TEMA.

- Results :

- 15 MW recovered,

- 40,000 t/year of HP steam,

- €2.5M/year saved,

- CO2 reduction of 12,000t/year.

Catalytic reforming – Feed effluent heat exchanger

- In a single piece of equipment, the product evaporates in a gas loop and is then pre-heated to a very high temperature (500°C) under high pressure (40 bars) using the effluent exiting at 550°C, which is cooled with the condensation of the treated product

- Results :

- 42m3/hour treatment using a 1,400m² _combined heat exchanger_ to save 31 MW of thermal power with a return on investment of less than 2 years.

Desulphurisation of coking plant gas

- 17 Ziebloc® heat and cool the different process stages and ensure thermal integration

- Highly fouling gas and liquids, heat exchangers with large plate spacing

- Wide variety of materials: Titanium, 904L, 316L depending on process stages

- 20m² to 350m² of exchange surface

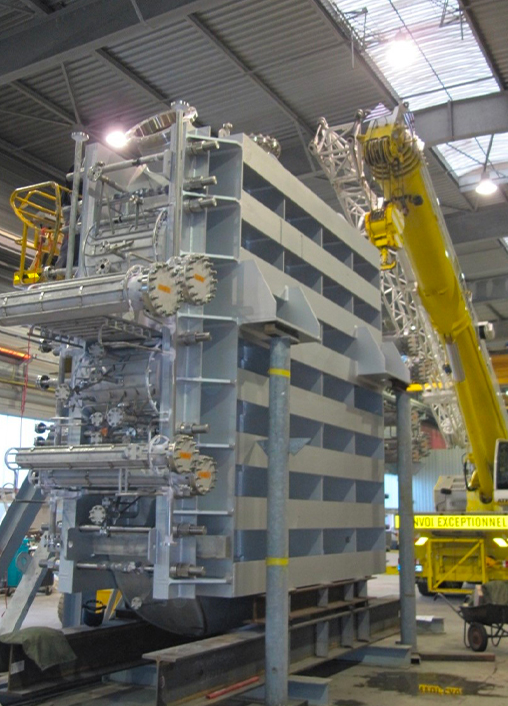

Heat exchanger reactor

The customer was looking to control a continuous polymerisation reaction:

- As the reaction is exothermic, the heat exchanger reactor evacuates the heat as it is generated by propylene evaporation

- The reagent is injected at different points of the equipment to control dilution and homogeneity

- Result: more even and similar molecules compared with a conventional process.

- The equipment in figures:

- L’appareil en chiffres :

- 950m² of exchange surface and

- 254 SMO,

- 25-bar design pressure,

- 600 weld inspection X-ray films,

- 10 fluid passes with 5 reagent injection lines + remixing designed using CFD

Vacuum column reboiler

For a vacuum distillation separation unit made up of 4 serial columns, replacement of the 4 shell and tube thermosiphon reboilers with welded plate devices.

- Corrosion resistance increased by replacing duplex with C276 alloy

- Debottlenecking with an exchange surface and coefficients increased by 30% within the same space as the previous equipment

- Easy to clean thanks to access doors

- Piping support and connections left unchanged to make installation easier

Do you have a project?

ZIEMEX supplies its expertise to refineries and petrochemicals units in the form of robust and efficient thermal equipment. Our solutions help control energy consumption and make your installations safer and more sustainable.