Home > Processing equipment for food processing

Processing equipment for food processing

Controlling your processes to boost your performance

ZIEMEX has been designing, manufacturing and installing process and chemical engineering equipment for over 60 years for the food processing and ingredients industry.

We control all the critical parameters: custom design, suggestion of subassemblies, compliance with standards, environments and construction codes, choice of specific materials, rigorous quality control and turnkey installation.

Our know-how is built on perfect control over processes, heat transfer and mechanical sizing. We provide solutions suited for each application, in direct connection with our range of processing equipment to guarantee high performance, safety and durability.

Continual adaptation

to the requirements of the food processing market

The processing of food and ingredients, such as starch, imposes high requirements:

- Strict compliance with regulations and construction codes (PED, CODAP, AD Merkblatt, ASME, etc.).

- Resistance to outside environments, pressures and temperatures.

- Incorporation of equipment into ATEX zones or other risky environments.

- Fiabilité et maintien des performances sur le long terme.aReliability and maintenance of performance over the long term.

ZIEMEX uses advanced manufacturing processes and selects suitable materials (stainless steel, titanium, Hastelloy, Inconel, duplex etc.) to meet those requirements.

This expertise is backed by our reactors, process tanks, columns, heat exchangers, skids, silos, and other process solutions.

ZIEMEX food processing and ingredients

solutions

We combine process engineering and know-how in custom manufacturing for each project:

Process reactors & tanks with controlled environments

Design suitable for complex reactions, with optional heating, cooling or agitation.

Distillation or absorption columns

Sized to maximise the efficiency of separation or concentration.

Storage

silos

Fully equipped storage and mixing silos with peripheral equipment: materials that resist aggressive products and temperature variations.

Each solution is developed in collaboration with our customers, integrating the requirements specific to their process.

Customer case

design and complete manufacturing of rum distillery plant in Cuba.

ZIEMEX has supported many food processing and ingredients companies both in France and internationally.

Some of our projects:

- High-pressure process tanks and reactors in stainless steel for sensitive operations.

- XXL distillation columns made to measure and incorporated into an ATEX zone.

- Heat exchangers designed for highly sticky and clogging products.

- Various fermenters for ingredient manufacturers

- Premium brown rum distillery for Havana Club: design and production of maturing vessels and design and complete manufacturing of a rum distillery in Cuba.

- 2008: first maturing vessel: over 20 tanks inerted with nitrogen, each with a capacity above 250m3, process piping, instrumentation and automation included

- 2014: second maturing vessel: over 20 tanks inerted with nitrogen, each with a capacity above 250m3, process piping, instrumentation and automation included

- 2017: third and fourth maturing vessel: over 2 x 20 tanks inerted with nitrogen, with capacity above 250m3 each, process piping, instrumentation and automation included, and connection to existing process building

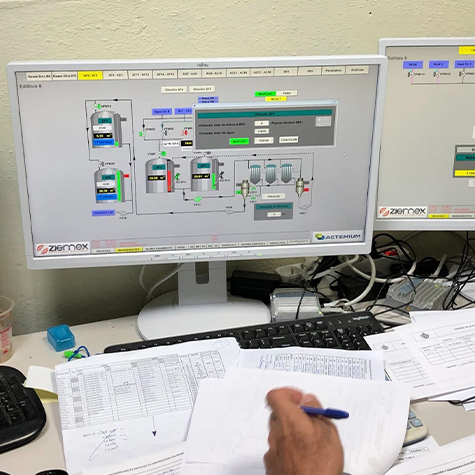

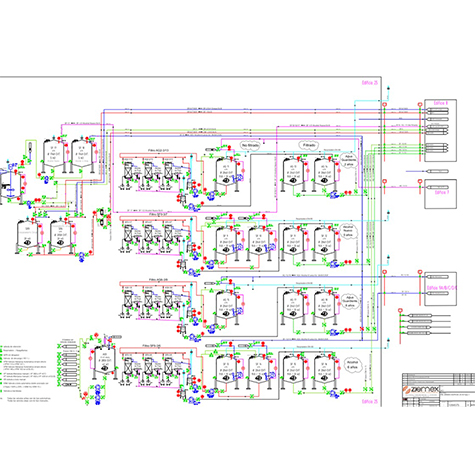

- 2023 and 2024: new process workshop for making rum including detailed engineering, PIDs, functional analysis, some hundred process tanks, carbon filters, 30km of process piping, over 300 process valves including hundred automatic valves, over 50 pumps, a new supervision system.

Do you have a project?

ZIEMEX provides the food processing industry with proven know-how and efficient equipment. Discover our equipment and get in touch to discuss your project.