Home > Processing equipment for breweries

Processing equipment for breweries

Over 60 years’ experience serving master brewers

Serving the brewing industry is the legacy business of ZIEMEX, and we have extensive expertise in the design and manufacture of complete subassemblies including fermenters and tanks of all types, for use in both the warm and cold blocks of the brewing process.

Each block has its own particular specifications for a smooth brewing process: For each project, ZIEMEX adapts the design, in terms of both the mechanical aspects of the vessel and safety for the end consumer, to produce high-quality beer while making sure that the equipment is perfectly integrated into the brewery.

Custom design and high fabrication quality are part of the ZIEMEX DNA, applied to guarantee the most demanding brewery processes

CONTINUAL ADAPTATION

to market requirements and developments

Changing consumer tastes are revolutionising the market, with a growing number of recipes: triple-fermented beer, hopped beer, flavoured beer and low-alcohol beer.

Breweries tend to change brews and recipes more frequently, which also requires adapting their tanks:

- Circulation loop for dry hopping on TOD-type fermenters

- Change in yeast strain with different fermentation profiles, impacting cooling requirements

- More frequent and more effective CIP/NEF cleaning cycles

ZIEMEX can support brewers in these changes through innovation and continual adaptation:

- Adaptable designs to optimise production and storage in line with new consumer tastes

- Variety of connections and incorporation of temperature and level sensors for complete control over the brewing process

- Efficient cooling systems for close control over fermentation

- Quality of surface conditions, variety of cleaning heads for optimum CIP and impeccable hygiene

- Insulation of individualised tanks

In order to help customers serve their new markets, ZIEMEX can provide expertise and solutions for complete subassemblies, with fermentation and other tanks that meet new requirements.

SOLUTIONS AND TANKS

for each block in the brewery

Brewing involves different processes that are divided into warm and cold blocks in the brewery: the warm block prepares the wort at a high temperature, mixing barley and then hops. In the cold area, the wort is turned into beer with the help of yeast in the fermentation phase, before it is filtered and stored.

The cold block contains several types of equipment:

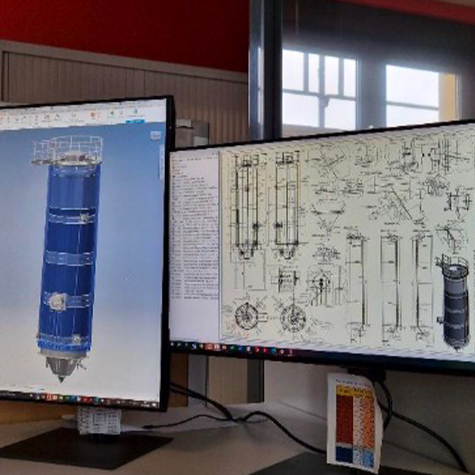

Outdoor/CCT fermentation tanks

For brewing wort into beer, with laser-welded cooling pillow plates, injected polyurethane insulation, stainless steel tank with improved surface quality for easy cleaning and impeccable hygiene.

BBT & TBF storage tanks

For storing the beer at low temperature before final packaging; insulated tanks with safety accessories suitable for storage pressures

Water tanks

For storing hot water for peripheral processes or storing glycol water used for cooling.

Spent grain silos

For storing spent grain; the grain mixture resulting from the manufacturing process is stored and repurposed as animal feed.

ZIEMEX is specialised in tanks for cold blocks, with particular expertise in fermentation tanks and complete control over the fermenter cooling process through laser-welded cooling pillow plates and their environment.

That know-how can also be applied to the warm, in which case the insulation and materials used are adapted accordingly and the cooling circuit is replaced by a hot water or steam heating system.

COMPREHENSIVE EXPERTISE

and local experience in breweries

ZIEMEX has been serving breweries for 60 years, helping customers size their tanks and oversee global project management, drawing on our extensive experience and the partners brought into the project.

- When we take charge of a project, our service includes logistics, unloading and handling of tanks, with supervision and assembly by our staff on site if necessary.

- Our supply may also be extended to include the addition of the instrumentation required for controlling fermentation in outdoor/CCT tanks, their levels, and the proper working of the CIP cleaning cycle

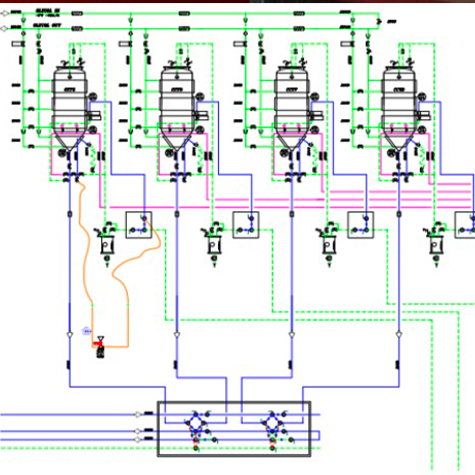

- The connection of sensors in the brewing room and all the piping required for the beer, CO2 and CIP can also be covered in a complete proposal with flow transfer panels for managing fluids.

Our teams have experience in managing several projects involving on-site assembly and complete integration to suit the requirements of the brewery:

- Delivery of pre-fabricated sheet metal tanks

- On-site assembly and welding for each component

- Assembly / injection of insulation

- Filling with water for pressure testing

CUSTOMER CASE

Several breweries in France and internationally have selected us for their end-to-end project

Brasserie du Mont Blanc : ZIEMEX was tasked with handling all of the integration work in a turnkey project for a cold block:

- Management of logistics, unloading and integration into the brewery

- Assembly of safety accessories and walkways

- Addition of custom walkways at the exact maintenance heights

- Integration of sensors reporting information to the tank supervision room

- Lastly, supply of all piping and the flow transfer panel for tanks with CIP and instrumentation

This meant the customer had a contractor partner managing the project as a whole, instead of going through multiple integrators which can lead to coordination and costing problems.

Thanks to our precise management of the project, from initial research, through to manufacturing and installation, our customer did not need to concern themselves with coordination requirements, particularly in the final logistics approach phase, allowing for quick, effective integration into the brewery and the adjoining taproom.

It was essential to work at a fast pace on site and ensure visual integration in order to satisfy our customer and their consumers, who visit the taproom to taste their different beers.

Advantages for the customer:

- Savings in engineering studies and supplier sourcing

- Technical integration to optimize TOD fermenter management

- Logistics responsibility transfer to a global partner to oversee the final unloading and crane operations on site.

- Visual integration within the brewery for local appeal and enhancement

- Commissioning by our specialist engineers

Do you have a project?

Talk to us about your project, whether it involves fermentation tanks, outdoor/CCT tanks, BBT storage tanks, water tanks or spent grain silos. ZIEMEX will help you benefit from our experience and handle your entire brewing equipment project from end to end.