Home > Our global solutions > Custom industrial evaporation and concentration equipment

Custom industrial evaporation and concentration equipment

Custom-made systems to combine energy performance, reliability and compact size

Evaporation and concentration is a key process in a number of industries, particularly chemicals, pharmaceuticals, food processing and sugar manufacturing, and aims to increase the concentration of a solution by separating part of the solvent through evaporation, and by condensing the vapour produced.

This process helps reduce the volumes to process, repurpose by-products or prepare for a crystallisation or formulation stage.

ZIEMEX evaporation and concentration solutions are custom designed to combine energy performance, reliability and compact size, while integrating perfectly into the customer’s processes.

Evaporation

Definition and requirements

Evaporation and concentration consists in thermally separating a solvent from a liquid mixture to concentrate the useful phase. It is used in many industrial applications:

- Food processing: concentration of juice, must or fermented products to reduce volumes and improve preservation.

- Pharmaceuticals & biotech: preparation of concentrated solutions before crystallisation or formulation, under controlled temperatures to preserve the active ingredients.

- Chemicals & fine chemicals: solvent recovery, concentration of reactant solutions or recovery of dissolved products in order to repurpose materials.

- Sugar manufacturing & distillery: concentration of juice, molasses or extracts to recover the product of interest with an eye to maintaining energy efficiency and reducing steam consumption.

By reducing energy consumption (through heat recovery and vapour recompression) and the transported volumes, evaporation and concentration contributes directly to decarbonising industrial processes.

ZIEMEX

Technology and know-how

ZIEMEX applies all the technologies required to make efficient and compact evaporation and concentration equipment:

- Z-compact thermosiphon boilers: natural circulation for stable evaporation with no recirculation pump, limiting head loss and fouling.

- Flash evaporation: instantaneous separation of the liquid-vapour mixture by pressure reduction, to ensure precise concentration and close control over efficiency.

- Zieplate falling film evaporators: the liquid is deposited in a fine film on the plates to maximise heat transfer and allow optimum cleaning.

- Z-compact high-efficiency condensers: recovery of energy from the condensed vapour to pre-heat the incoming fluid.

- Energy optimisation: possibility of integrating mechanical vapour recompression (MVR) or a heat pump to reduce the consumption of steam and utilities.

ZIEMEX equipment is designed to operate in high-vacuum or high-pressure conditions, to guarantee precise temperature control, high reliability and simplified operation.

Benefits

for your processes

ZIEMEX evaporation and concentration solutions offer significant benefits for your processes:

- Optimised energy performance: integration of Z-compact® or Zieplate heat exchangers to reduce the consumption of vapour and limit heat loss.

- Control of concentration: precise control of the solute rate to guarantee the quality and reproducibility of the end product.

- Flexibility and modularity: modular skids that can adapt to space constraints and the processed volumes.

- Safety and reliability: robust equipment designed for continuous operation with easy maintenance.

- Use of by-products: efficient recovery and concentration to optimise yield and reduce losses.

Associated

services

ZIEMEX supports its customers throughout the life cycle of their equipment and processes:

Custom preliminary design and design

Integration of process, thermal and mechanical requirements from the quotation stage. The studies take into account the need for concentration, decarbonising and energy efficiency.

Factory design and manufacturing

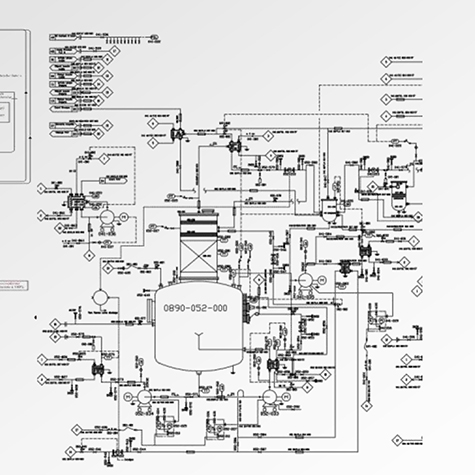

3D design using Inventor, mechanical and thermal calculations, PIDs, definition of equipment and monitoring of manufacturing. Compliance with design codes (ASME, CODAP, EN 13445, AD 2000) and the PED.

Testing and validation

Factory Acceptance Test (FAT) at our production facilities and Site Acceptance Test (SAT) at the customer’s site. Process validation and adjustment of parameters before entry into production.

R&D and pilot station

Possibility to test the process on our test station: fermentation, distillation, evaporation, crystallisation etc. These tests validate the thermal balance and product behaviour before transfer to the industrial scale.

Maintenance and long-term monitoring

Technical support, periodic inspection, thermal or mechanical audit, adaptation of equipment to process changes.

Get in touch with our teams

Evaporation and concentration is a key process in reducing the volumes to process, repurposing products and optimising the energy performance of your installations. ZIEMEX has the expertise to support you from preliminary design to commissioning, for reliable custom-made solutions. Contact our experts to design your evaporation and concentration skid and ensure the success of your project.