In the icy and demanding world of space exploration, every piece of equipment must demonstrate flawless reliability. It is in this extreme context that ZIEMEX’s Radiaplaques®, embossed double jackets, and radiant panels have established themselves as reference solutions for over 30 years.

Simple, effective… and tailored for space

Behind their apparent simplicity lies high technicality. These devices are designed to manage thermal transfers in cryogenic environments, particularly within space simulation chambers used to reproduce the conditions of vacuum and extreme cold that satellite equipment undergoes.

Resistance to intense thermal shocks

La grande force de ces équipements ? Leur capacité à The great strength of this equipment? Their ability to withstand violent and rapid thermal cycles, where other conventional technologies eventually fail. Thanks to high-precision laser welding technology, ZIEMEX guarantees exceptional mechanical strength, without deformation or leakage.

Leak-tightness guaranteed by helium tests

Each Radiaplaque® or radiant panel is subjected to helium leak tests, one of the most diffusive gases, to guarantee absolute leak-tightness, essential in vacuum environments.

Proven technology, custom manufacturing

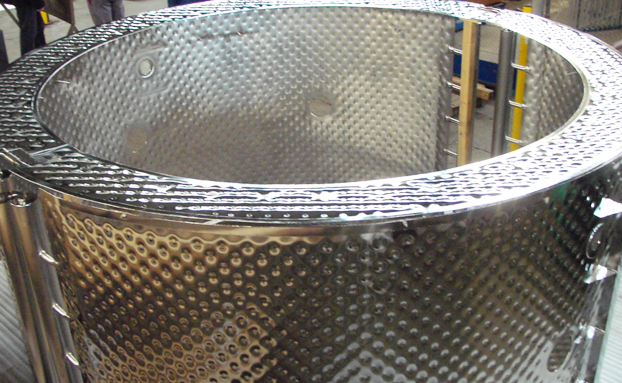

Made of stainless steel or titanium according to the client’s requirements, the Radiaplaques® consist of two sheets welded by laser, then formed by hydroforming, creating an ultra-efficient internal thermal circuit. ZIEMEX offers several standard formats (type T, S, or titanium), with surfaces ranging from 0.36 to over 2.5 m², permissible pressures up to 15 bar, and great mounting flexibility.

For players in hi-tech and space

Whether for cryogenic screens, radiant panels for satellites, or devices for thermal simulation chambers, ZIEMEX is a recognized partner of the aerospace industry and high-tech R&D. Its solutions are already deployed in leading space centers and laboratories around the world.

Want to go further?

ZIEMEX designs and manufactures your custom thermal equipment, in stainless steel, titanium, or special alloys, to meet the most severe requirements of the space, nuclear, or cryogenic industry.