Home > Our global solutions > Industrial heat exchange

Industrial heat exchange

High performance, efficiency and ZIEMEX know-how

Industrial heat exchange consists in transferring thermal energy between two fluids or between a wall and a product.

In industry, controlling heat exchange is a key factor for efficiency and durability. Whether for heating, cooling, condensing, evaporating or keeping a product at a constant temperature, thermal solutions directly influence the quality of processes, energy costs and the safety of installations.

ZIEMEX has been developing unique expertise for over 30 years in the area of heat exchange applied to tanks, reactors, fermenters and processing equipment.

Thanks to our single embossed pillow plate technology, our welded plate heat exchangers, shell and tube exchangers or those incorporated into complete skids, we have the ability to guarantee measurable thermal performance suited to your industrial requirements.

Thermal challenges

for each industrial sector

Control over heat exchange plays a central part in the performance and sustainability of industrial processes. Each industry has its own challenges due to the products handled, regulatory requirements and the search for energy efficiency. ZIEMEX helps customers achieve this optimisation by adapting its thermal technologies to each production environment.

- Food & Beverage & Brewery: optimization of cooling cycles to preserve microbiological quality.

- Pharmaceutical & Biotech: strict control of thermal profiles to preserve the integrity of sensitive molecules.

- Chimie : maîtrise de la condensation des fluides process selon température et pression.

- Petrochemicals: management of high temperatures and extreme pressures

- Sugar and distillery: validation of our heat transfer coefficients for evaporation using our pilot station

ZIEMEX technology &

know-how

ZIEMEX designs and builds thermal solutions that are suited to every need:

- Single embossed pillow plates :

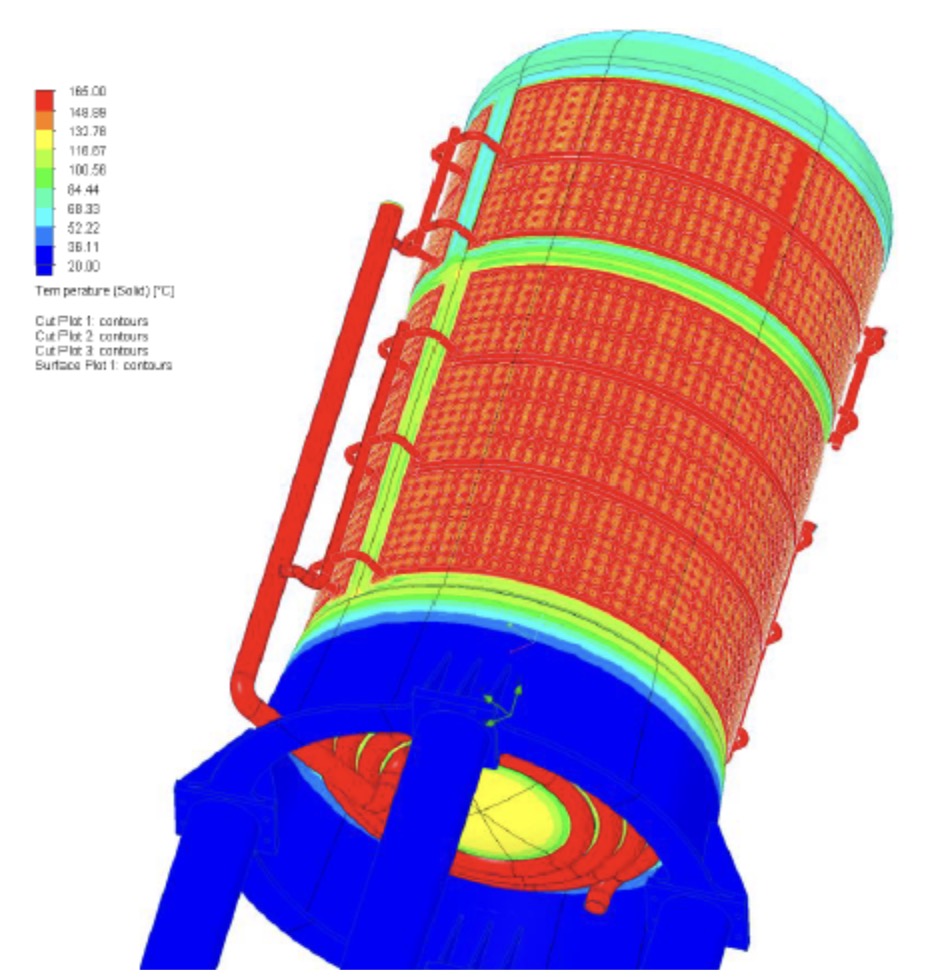

- Heating/cooling curve calculations based on the product, agitation system and tank geometry.

- Thermal performance guaranteed from the design phase.

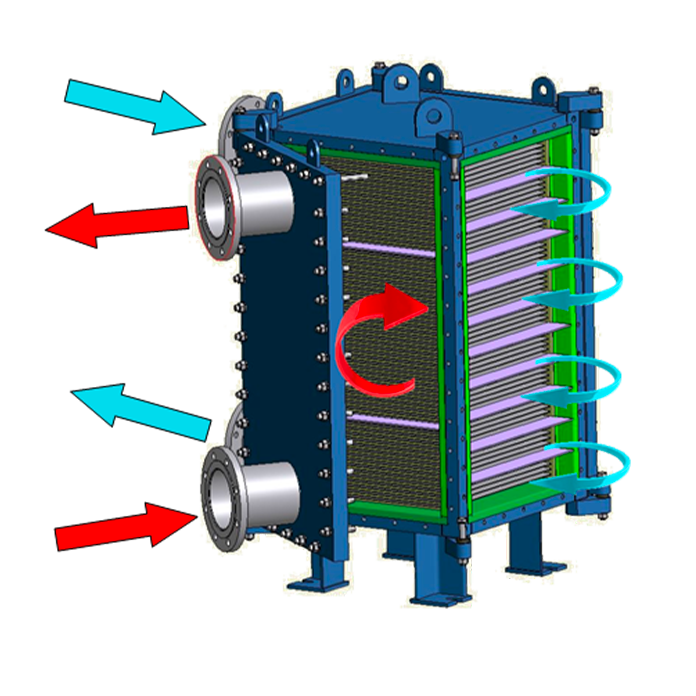

- Welded plate heat exchangers :

- Crossflow, counterflow or specific operation via our U plates.

- Compact design, adaptability and high performance for your processes.

- Shell & tube heat exchangers :

- Sizing with HTRI software, global standard setter for thermal design.

- Ideal for high pressures, high temperatures or complex fluids.

- Thermal skids :

- Integrated design for temperature control of your processes.

- Thermal design that takes account of agitation, wall thickness and coefficient convection.

Associated services

beyond equipment supply

ZIEMEX supports each project from design to commissioning: our engineers carry out personalised thermal design studies including sizing and heating/cooling curves, followed by custom production and turnkey installation, performance validation via Factory Acceptance Tests (FAT), and start-up support. We also offer maintenance and optimisation services for your existing plant to guarantee lasting and sustainable efficiency.

benefits

for your processes

Our heat exchange solutions provide tangible benefits:

- Productivity gains: optimised heating and cooling cycles.

- Reduced energy costs: improved thermal integration, less loss.

- Regulatory compliance: design to ASME, CODAP, EN 13445, PED, etc.

- Reliability and sustainability: equipment designed to withstand harsh conditions

- Performance commitment: ZIEMEX is committed to achieving the thermal results expected.

Do you have a project?

With 30 years’ know-how and a complete range of thermal equipment, ZIEMEX is your go-to partner for the energy optimisation and control of industrial thermal processes. Get in touch to look over your project or learn more about our thermal equipment.