Home > Custom industrial heat exchangers > Z-tubex shell & tube heat exchangers

Z-tubex shell & tube heat exchangers

High performance and robustness

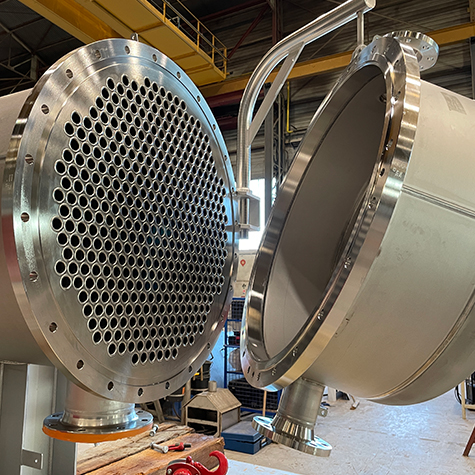

Z-tubex shell & tube heat exchangers are designed to offer top thermal performance while also guaranteeing maximum mechanical robustness.

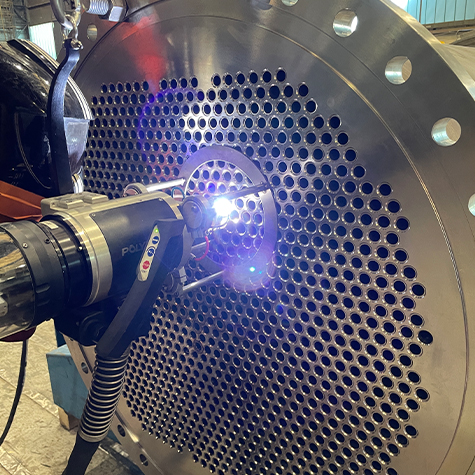

Their proven design and the precision fabrication thanks to latest-generation systems make it possible to meet the most demanding applications, whether high pressure, extreme temperature or cyclical operating conditions.

[All thermal design work is done in-house by our staff using the HTRI sizing software,](Tous les calculs thermiques sont réalisés en interne par nos équipes à l’aide du logiciel de dimensionnement HTRI,) to guarantee reliable and optimised sizing for each application.

Z-tubex®

Solutions

Z-tubex heat exchangers are characterised by their exceptional reliability and adaptability. Their tubular design offers very high resistance to thermal shocks and mechanical impacts, while allowing complete customisation to meet the specific requirements of each installation.

The tubes can be made straight, U-shaped or coiled, thus offering total flexibility for configuring and optimising thermal performance.

Maintenance and inspection are simplified with removable collection boxes, which provide direct access to the tubular plates and the inside of the tubes. This design reduces down time and allows quick and efficient maintenance, whether it involves mechanical or chemical cleaning, in order to maintain consistent performance over time.

In order to adapt to all the requirements of the process and maintenance, Z-tubex can be designed in accordance with TEMA (Tubular Exchanger Manufacturers Association) international standards. The classification uses three letters: the first refers to the design of the front-end head, the second that of the shell, and the third that of the rear-end head. A few examples to illustrate the nomenclature:

- AES: channel and removable cover – one-pass shell – floating head with backing device

- BEM: bonnet (integral cover) – one-pass shell – fixed rear-end head

- CFU: integral front-end head – shell with segment baffles – rear-end head in U-tube

- Energy economisers

This classification makes it possible to select the configuration best suited to the specific needs of each application, whether for cleaning, thermal expansion or maintenance.

The performance guarantee of Z-tubex relies on a custom thermal, hydraulic and mechanical design, validated by accurate and tested calculations. Each piece of equipment is designed to provide maximum reliability and optimum efficiency, even in the most demanding service conditions.

Technical specifications

to boost your performance

We make Z-tubex heat exchangers in the material best suited to your process. That may be standard stainless steel such as 304L or 316L, corrosion-resistant stainless steel such as 904L or 310L, duplex, super duplex, titanium, Hastelloy® C22, C276 or C2000, Inconel® or zirconium.

The permissible temperature ranges extend from -200°C to +1150°C, thus covering cryogenic processes and moderate-temperature applications alike. ZIEMEX Z-tubex exchangers are sized for operating in absolute vacuum (-1 barg) and can withstand pressures up to 200 barg.

Example

of use

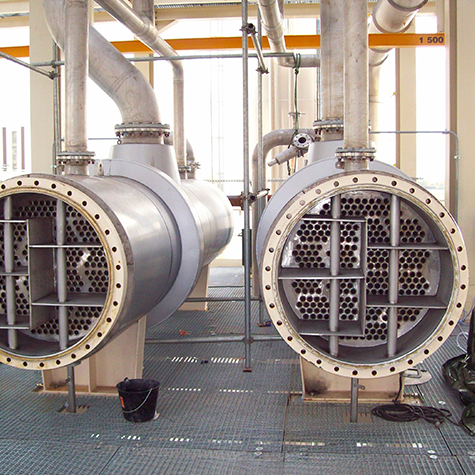

For a customer in the chemicals industry, ZIEMEX designed a Z-tubex exchanger that acts as a CO₂ economiser, made in [compliance with ASME U-Stamp and KGS certification.](conformité avec l’ASME U-Stamp et la certification KGS.)

The equipment was made in 316Ti stainless steel in order to withstand severe service conditions with maximum permissible temperature (TS) of 550°C and service pressure (PS) of 30 barg.

In order to limit the stresses linked to thermal expansion, the TEMA configuration selected was of the BFU type. This solution offers several benefits:

- A U-tube bundle that can be removed for easy cleaning,

- Bent U-tubes that can expand freely, thus reducing mechanical stresses,

- A longitudinal baffle to ensure that the counterflow is virtually perfect,

- Reduced thermal pinch, for optimum energy recovery.

This example illustrates the ability of Z-tubex shell & tube heat exchangers to adapt to the most demanding conditions, while combining mechanical strength, energy performance and ease of maintenance.

Do you have a project?

Talk to us about your dimensional, process and layout requirements.

Our engineers are on hand to support you from design to installation.