Home > Processing equipment > Custom industrial heat exchangers

Custom industrial heat exchangers

for optimum performance

Heat exchangers are vital for a number of industrial processes, whether it is for heating, cooling, condensing or evaporating fluids. They are used in food processing, fine chemicals, pharmaceuticals and energy, and must combine high thermal performance, mechanical reliability and resistance to the most demanding environments.

At ZIEMEX, we size the thermal and mechanical characteristics of each device entirely before manufacturing the exchangers, in order to satisfy the process parameters and requirements specific to each customer.

We determine the most suitable technology to optimise the performance and life of the installation based on your process requirements: type of fluid, possible presence of deposit, pressure, temperature, layout configuration. Our designs are suitable for both clean fluids and for highly fouling products as they allow easy access and cleaning.

OUR HEAT EXCHANGERS FULFIL ALL KEY THERMAL FUNCTIONS:

- Falling film or thermosiphon evaporators

- Vacuum condensers

- Coolers or heaters

- Economisers

OUR EXPERTISE IN

heat exchange

Our strength lies in complete control over the design process:

- Integrated thermal and mechanical calculations, with exchange modeling to ensure precise sizing.

- Material and technology selection based on corrosion resistance, temperature, pressure, and fluid type.

- Custom manufacturing in our workshops, complying with international standards (DESP, ASME, FDA, etc.).

- Technical support from design to commissioning, with a single point of contact for greater responsiveness.

THERMAL FUNCTIONS

available

Each industrial process imposes its own requirements: type of fluid, pressure and temperature levels, hygiene requirements, available space, etc.

At ZIEMEX, we design custom heat exchangers, selecting the technology that best fits your needs.

Whether the aim is to maximise heat transfer, make cleaning easier, withstand corrosive environments or reduce the space taken up on the floor, we have a complete range of proven solutions, all designed and manufactured in our facilities in France.

Condenser

A condenser is a heat exchanger that converts vapor into liquid by lowering its temperature using a cooling medium (water or air).

Used in chemistry, distillation, or vacuum processes, it condenses vapours while recovering latent heat to improve energy efficiency.

Falling film evaporator

Such evaporators are designed to concentrate product by making the fluid flow in a fine layer along heated walls.

This configuration is conducive to rapid heat exchange and limits the residence time, which is ideal for heat-sensitive or viscous products.

Cooler

A cooler is used to lower the temperature of a liquid or gas before it is stored, processed or conditioned.

It may operate with water, heat-transfer fluid or air as the cooling means.

Economiser

An economiser recovers the residual heat from a fluid (often fumes or hot gas) to preheat another fluid that is used by the process.

Recovering energy in this way improves overall efficiency and reduces energy consumption.

Cette récupération d’énergie améliore le rendement global et réduit la consommation énergétique.

Thermosiphon evaporator

This type of evaporator uses the natural circulation induced by the difference in density between the heated liquid and the cooled liquid.

It is particularly suitable to continuous processes, where mechanical simplicity and reliability are crucial.

Heater

A heater raises the temperature of a fluid in order to prepare it for a chemical reaction, heat treatment or a processing stage.

It may use steam, thermal oil or another hot fluid as its energy source.

OUR HEAT EXCHANGER

solutions

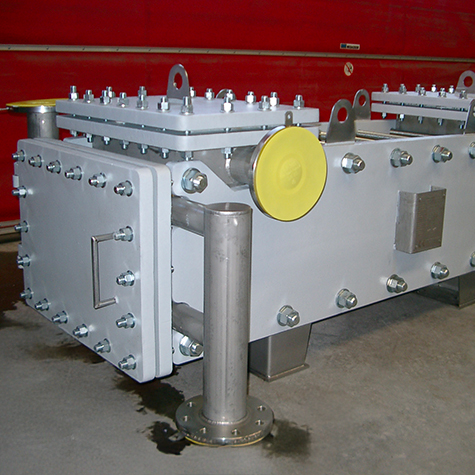

Z-compact®

The Z-compact® heat exchanger is made up of a bundle of welded plates incorporated into a cylindrical shell.

Available in fully welded version or inspectable/cleanable on one shell circuit or even both circuits depending on the application.

Ideal for combining compactness and mechanical robustness.

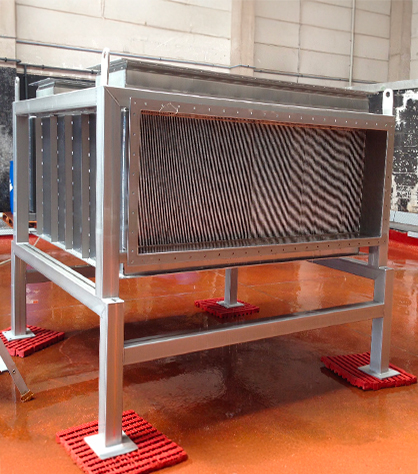

Zieplate®

Zieplate® is a horizontal rectangular heat exchanger with doors on one or two circuits.

Its design allows perfect counterflow use, maximising thermal efficiency.

Ziebloc®

A vertical rectangular heat exchanger with four doors that offer full access to the two circuits for inspection and mechanical cleaning.

Ziepack®

Ziepack® is a heat exchanger with a large surface, often used for vacuum condensers requiring a high cooling water flow rate.

Z-tubex®

Z-tubex® is a shell & tube heat exchanger that can carry out all functions (condenser, evaporator, cooler, etc.).

Designed according to TEMA standards using HTRI software and available in all types of tubular configuration.

Pillow plates

Our welded pillow plates are designed to be incorporated into equipment such as crystallisers, scraped surface heat exchangers or other specific processes.

SINGLE EMBOSSED PILLOW PLATES

Made to heat or cool a tank, reactor or fermenter using a utility fluid (water, steam etc.).

Designed with a fine plate and thicker plate so as to only deform on the useful side.

Radiaplaque®

Radiaplaque® plates offer indirect heating/cooling system by allowing heat exchange via immersion.

Do you have a project?

ZIEMEX can support you from the very early stages of design up to commissioning of compliant, sustainable and efficient equipment.