Home > Our global solutions > Custom industrial distillation

Custom industrial distillation

Energy performance, purity control and optimal integration in your processes

Distillation is an essential separation process in many industrial sectors, particularly for chemicals, pharmacy, petrochemicals and solvent development.

It relies on the difference in volatility of the ingredients in a liquid mixture, enabling pure or concentrated fractions to be obtained through successive evaporation and condensation.

At ZIEMEX, we design and manufacture custom distillation solutions, combining energy performance, purity control and optimal integration in your processes.

Each installation is designed to meet your technical, regulatory and environmental requirements.

Industrial distillation

Definition and requirements

Distillation processes play a key role in product development and purification, but they also reduce discharges and decarbonise industrial processes.

Main aims :

- Increased purity of distilled fractions (solvents, monomers, reaction intermediates, etc.).

- Optimised energy consumption maximising heat recovery within the process.

- Reduced emissions and product loss due to efficient condensation and precise temperature control.

- Guaranteed stability and safety of operations, even at high temperatures or in a high vacuum.

At ZIEMEX, we are committed to a comprehensive energy efficiency and decarbonisation approach, integrating the most high-performance solutions in our designs: multi-level condensers, mechanical vapour recompression, energy recovery and optimisation of thermal flows.

Ziemex

technology and know-how

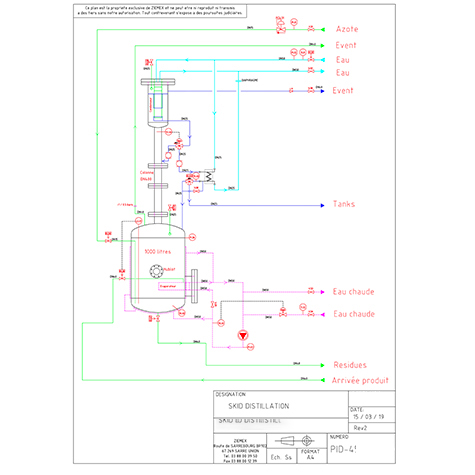

At ZIEMEX, we design complete distillation solutions, integrating all the key elements of the process, such as the distiller, the column and the condenser. This guarantees performance, purity and energy efficiency.

- Z-compact® distillers at the column base : ensuring uniform, stable vaporisation, preventing problems with fouling and optimising the process’s energy performance.

- Custom distillation columns : manufactured in our production facilities, with their internal components (plates, trims, demister, etc.) sized in line with the product, pressure and desired separation rate.

- Z-compact® condensers or multi-level Zieplates : enabling progressive condensation and maximum heat recovery, reducing the need for utilities.

- Energy efficiency and decarbonisation: option to integrate mechanical vapour recompression or heat pump systems to reduce vapour consumption and the installation’s carbon footprint.

Our solutions are suited to a wide range of conditions and all types of fluids, from the cleanest to the most fouling. Designed for reliable operation, reduced fouling and simplified cleaning, ZIEMEX distillation systems combine performance, durability and energy optimisation.

benefits

for your processes

ZIEMEX evaporation and concentration solutions offer significant benefits for your processes:

- Energy performance: integration of economisers and heat recovery to reduce vapour requirements

- Controlled purity: precise temperature and pressure control to guarantee the quality of the distilled product.

- Environmental optimisation: maximal vapour condensation → reduced discharges and utilities consumption.

- Process flexibility: suitability for products, operational conditions and industrial standards.

- Reliability and safety: robust design, material traceability and compliance with the most rigorous standards.

Associated

services

ZIEMEX supports its customers throughout the life cycle of their equipment and processes:

Custom preliminary design and design

Integration of process, thermal and mechanical requirements from the quotation stage. The studies take into account the need for concentration, decarbonising and energy efficiency.

Factory design and manufacturing

3D design using Inventor, mechanical and thermal calculations, PIDs, definition of equipment and monitoring of manufacturing. Compliance with design codes (ASME, CODAP, EN 13445, AD 2000) and the PED.

Testing and validation

Factory Acceptance Test (FAT) at our production facilities and Site Acceptance Test (SAT) at the customer’s site. Process validation and adjustment of parameters before entry into production.

R&D and pilot station

Possibility to test the process on our test station: fermentation, distillation, evaporation, crystallisation etc. These tests validate the thermal balance and product behaviour before transfer to the industrial scale.

Maintenance and long-term monitoring

Technical support, periodic inspection, thermal or mechanical audit, adaptation of equipment to process changes.

Get in touch with our teams

Industrial distillation requires perfect control of heat transfer, high purity requirements and ongoing energy optimisation. At ZIEMEX, we support industrial companies in designing high-performance, durable, decarbonised distillation solutions. Get in touch with our experts to design a distillation skid tailored to your processes.