Home > Our global solutions > Cleaning In Place (CIP) / Hygiene & Sterilisation in Place (SIP)

Cleaning In Place (CIP) / Hygiene & Sterilisation in Place (SIP)

ZIEMEX’s requirements for health safety.

Within the food processing sector, regulation CE 852/2004 establishes hygiene rules and obligations for operators in order to guarantee consumer health.

The brewery industry is, therefore, subject to this regulation.

As an equipment manufacturer for this sector, our goal at ZIEMEX is to use our expertise and know-how to ensure that any equipment provided to breweries operates precisely as outlined in the regulations.

As these regulatory requirements are also extremely relevant for other sectors, such as pharma and biotech, ZIEMEX equipment is designed to be compliant, particularly in terms of hygiene.

Cleaning in Place (CIP)

aim, stages and advantages for your industrial processes

Le CIP, Cleaning in Place ou NEP pour nettoyage En Place, est un processus de nettoyage en boucle fermé, sans démonter les équipements concernés.

This washing process cleans, rinses and disinfects any equipment parts that may have been contaminated by bacteria, solid waste or liquid waste, and which may therefore pose a health risk to the consumer.

An additional step may be required using SIP, which adds a final Sterilisation stage to eliminate 100% of the microorganisms – the only final condition required for the equipment to be “sterile”.

The tank rinsing circuits are the active parts of TOD/CCT fermentation tanks. These are generally activated by a solution sprayed through a static or rotary spray ball from a variety of angles, in order to cover all contact surfaces.

.

ZIEMEX’s expertise

CIP/SIP compatible equipment design for industrial hygiene

Wherever yeast, fermentation waste and scale are present in TOD/CCT fermenters, biofilms and bacteria can adhere and be produced.

ZIEMEX’s expertise in manufacturing this equipment is evident in the surface finish of the sheet metal we use. The roughness is < 0.6 microns, where required, i.e. less than the estimated size of a bacterium, at 1 micron!

It should be noted that the roughness must be controlled throughout the manufacturing chain. Once the sheet metal has been formed and welded, all surfaces that will come into contact with the fermentation wort or beer must have the precise surface finish required. At ZIEMEX, we have special grinding machines, XXL machines, and our own pickling/passivation station which can treat surfaces, such as welds that have been ground, guaranteeing a quality finish for our customers

Design and performance

of CIP/SIP cleaning tanks

Each design detail plays an essential role in the effectiveness of cleaning in place.

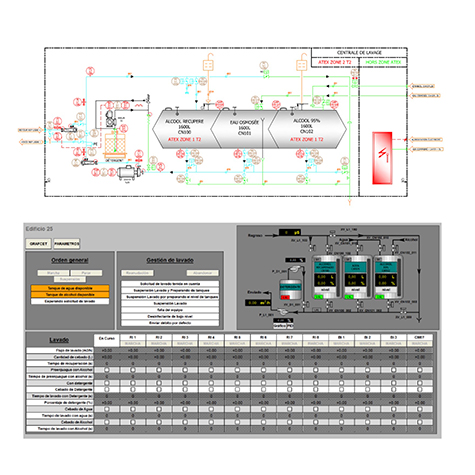

At ZIEMEX, the tank geometry, choice of materials and washing process control are designed to guarantee full, rapid cleaning with no retention.

Tanks intended for CIP and sterilisation in place are designed to withstand mechanical, thermal and chemical forces, while guaranteeing flawless hygiene.

From the choice of cone-shaped food-safe stainless steel which promotes full drainage of fluids, to the integration of customised cleaning devices (static, rotating or jet balls), each ZIEMEX tank is carefully designed to optimise the circulation of cleaning solutions and prevent any risk of cross contamination.

Where there is contact with food, stainless steels are preferred, and any distinctions are adapted as appropriate for the tanks in question.

At ZIEMEX, we are able to work with any food-safe stainless steel and produce storage tanks for CIP fluids.

Most TOD/CCT fermentation tanks feature a conical bottom not only for yeast and beer recovery but also to facilitate the drainage of CIP fluids and ensure no mixing occurs between the future wort and any CIP residues.

Special attention must be given to drainage surfaces, flanges, seal faces, and swivel points to ensure complete fluid evacuation without residue or cross-contamination.

Fermenters typically follow cleaning cycles using alkaline solutions for organic matter, followed by acid for mineral deposits, and then disinfection. These fluids flow from the top of the tank through a CIP port to cover the interior, with the goal of maximizing surface coverage and avoiding any “shadow” areas that remain unwetted.

To ensure proper dispersion, our tanks can be equipped with all cleaning devices available on the market—from static perforated balls to rotary and jet versions. We integrate any design, considering the final height and required operating pressures, not only to rinse and disinfect the tank but also to ensure that all safety accessories, fittings, and sensors are thoroughly cleaned.

Temperatures usually do not exceed 50°C. However, ZIEMEX can account for significant temperature variations and study potential vacuum conditions caused by these changes if the brewery performs CIP cleaning at temperatures above 85°C. Inadequate tank design in such cases can lead to tank collapse due to air volume contraction during cooling.

In the specific case of sterilization, temperatures can reach up to 130°C.

Benefits

for your processes

The integration of a high-performance CIP/SIP system offers so much more than cleaning: it has a direct effect on your processes, improving their effectiveness and safety.

By guaranteeing perfect hygiene, cleaning in place:

- reduces down time between cycles,

- limits manual intervention,

- increases the useful life of the equipment.

Thanks to ZIEMEX’s expertise in dimensioning, surface finishes and internal tank design, we can ensure the complete elimination of residues, with no dead zones or cross contamination.

Result : stable performance, optimised water and cleaning product consumption, full compliance with health regulations (FDA, GMP, PED), and increased productivity across the entire processing line.

Get in touch with our teams

Are you looking to design or adapt your equipment for effective cleaning in place and sterilisation in place? Our engineers can help you define the most suitable CIP/SIP solution for your processes, sanitary requirements and performance goals.